Exploring the Efficiency and Versatility of Overhead and Gantry Cranes in Modern Industries

Overhead and Gantry Cranes Key Components of Modern Industry

In the realm of material handling, overhead and gantry cranes play a pivotal role, serving as essential machinery that enhances productivity and efficiency across various sectors. These cranes are designed to lift and move heavy loads with precision, making them indispensable in factories, warehouses, shipyards, and construction sites.

What Are Overhead and Gantry Cranes?

Overhead cranes, as the name suggests, are systems consisting of a horizontal beam supported by vertical columns, where the lifting mechanism travels along the beam. Similar to overhead cranes, gantry cranes have a bridge that spans across the work area but they are supported on legs that move on wheels or tracks, which provides more flexibility in movement compared to fixed systems.

Design and Functionality

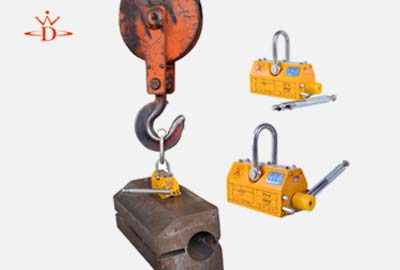

Overhead and gantry cranes can be tailored to specific needs, with a range of designs and configurations available. They come equipped with various lifting mechanisms, including hooks, magnets, and specialized attachments, allowing them to handle diverse types of materials. The lifting capacity can vary dramatically; some cranes can lift several tons, making them suitable for heavy industrial applications.

Both types of cranes can be categorized into two main types single girder and double girder. Single girder cranes are lighter and more cost-effective but have limited lifting capacity and span. On the other hand, double girder cranes offer greater strength and can handle heavier loads, though they require more space and investment.

Advantages of Overhead and Gantry Cranes

1. Space Efficiency Overhead and gantry cranes free up floor space, allowing for more efficient use of the workspace. The lifted loads do not obstruct pedestrian or vehicle traffic beneath the crane, enhancing safety.

overhead and gantry cranes

2. Increased Productivity These cranes significantly reduce the time needed for lifting and moving materials. Their speed and precision contribute to improved workflow and employee efficiency.

3. Versatility Overhead and gantry cranes can accommodate various attachments for specific lifting needs, making them versatile for different industries. For instance, hook attachments are often used in manufacturing, while magnets are utilized in scrap yards for handling metal debris.

4. Safety Modern overhead and gantry cranes are equipped with advanced safety features such as overload protection, limit switches, and emergency stop buttons. These elements help minimize the risk of accidents and injuries in the workplace.

Challenges and Considerations

While overhead and gantry cranes offer many advantages, they also come with challenges. Regular maintenance is crucial to ensure their smooth operation and to adhere to safety standards. Neglecting maintenance can lead to equipment failure, which can halt production and pose safety risks.

Furthermore, the initial investment required for purchasing and installing these cranes can be significant. Organizations must weigh the potential return on investment against the costs. Proper training for operators is also essential to maximize the effectiveness of the cranes and ensure compliance with safety regulations.

Conclusion

In conclusion, overhead and gantry cranes serve as vital components of modern industrial operations. Their ability to efficiently handle heavy loads while saving space and enhancing safety makes them invaluable assets. With the right design, maintenance, and operator training, these cranes can significantly contribute to the efficiency and productivity of various industries, proving that they are more than just machinery; they are the backbone of material handling systems worldwide.

-

4000 lb Gantry Crane | Adjustable, Heavy-Duty Lifting SolutionsNewsAug.31,2025

-

Portable 2000 lb Gantry Crane | Heavy-Duty & AdjustableNewsAug.30,2025

-

Versatile Lifting Solutions with Gantry and Overhead CranesNewsAug.29,2025

-

The Versatile Mobile Gantry Crane SolutionNewsAug.29,2025

-

Reliable Movement with Heavy Machinery Skates and RollersNewsAug.29,2025

-

Reliable Lifting Performance with 2000 lb Gantry Crane and 2 Ton Overhead SystemsNewsAug.29,2025

-

Maximize Lifting Efficiency with PML Magnetic LiftersNewsAug.29,2025