Exploring the Functions and Applications of Gantry Cranes and Hoists in Modern Industry

Understanding the Gantry Crane and Hoist A Key Element in Material Handling

In the world of construction, manufacturing, and logistics, the efficiency of material handling plays a crucial role in productivity and safety. Among the various tools employed in these industries, gantry cranes and hoists stand out as indispensable equipment designed to lift and move heavy loads with precision and ease.

A gantry crane is a type of overhead crane that consists of a high frame structure, supported by legs that move along wheels or on fixed tracks. Its design allows for the lifting and transporting of large, cumbersome items across long distances, making it an ideal choice for outdoor applications, such as shipping yards, heavy manufacturing plants, and warehouses. The gantry crane is available in various sizes and configurations, tailored to meet the specific needs of any operation.

Understanding the Gantry Crane and Hoist A Key Element in Material Handling

Hoists, on the other hand, are mechanical devices used to lift and lower loads vertically. They can be integrated into gantry cranes or used independently. A hoist consists of a rope or chain, a drum or wheel, and a motor that provides the necessary power for raising and lowering the load. Electric hoists are particularly popular due to their efficiency and ability to handle heavy loads with minimal manual effort.

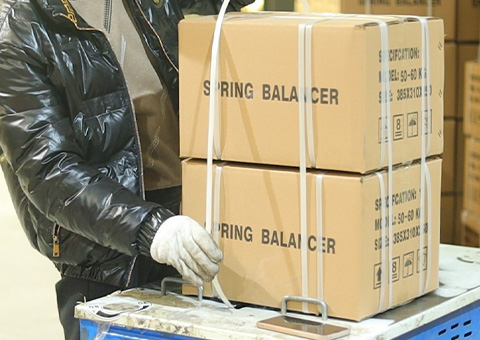

gantry crane and hoist

The combination of a gantry crane and a hoist creates a powerful system for managing heavy materials. When utilized together, they enhance the safety and efficiency of lifting operations. The gantry crane provides the framework to support the hoist, while the hoist performs the lifting tasks. This partnership enables workers to move items that could be unsafe or impossible to handle manually, significantly reducing the risk of injuries.

Safety is a paramount consideration in the operation of gantry cranes and hoists. Operators must be trained in the proper use of these devices, including load limits, stability precautions, and emergency procedures. Regular inspections and maintenance are also essential to ensure that both the crane and hoist are in optimal working condition, preventing accidents caused by equipment malfunction.

In addition to their safety features, advancements in technology have significantly improved the functionality of gantry cranes and hoists. Modern systems are equipped with sophisticated controls that allow for precise movements, remote operation, and integration with other automated systems. Increased use of sensors and smart technologies enhances safety and increases efficiency, allowing for real-time monitoring of load weights and movement patterns.

In conclusion, gantry cranes and hoists play a vital role in various industries, providing a reliable solution for lifting and transporting heavy materials. Their versatility, coupled with advances in technology, ensures that they remain essential components in improving work efficiency and safety. As industries continue to evolve, the demand for effective material handling solutions like gantry cranes and hoists will only continue to grow, highlighting the importance of these powerful tools in the modern workplace. With proper training, maintenance, and operational practices, gantry cranes and hoists will undoubtedly continue to be integral in maximizing productivity across a range of applications.

-

The Ultimate Guide to Heavy Machinery Moving EquipmentNewsAug.04,2025

-

The Evolution of Large Equipment MoversNewsAug.04,2025

-

Maximizing Efficiency with PML Magnetic Lifters in Industrial OperationsNewsAug.04,2025

-

Choosing the Best Small Gantry CraneNewsAug.04,2025

-

Innovations in Permanent Lifting Magnet TechnologyNewsAug.04,2025

-

How to Maintain Your Adjustable Gantry Crane for LongevityNewsAug.04,2025

-

PML 6 Lifting Magnet Troubleshooting GuideNewsJul.25,2025