forklift magnetic lifter

The Importance of Forklift Magnetic Lifters in Material Handling

In the fast-paced world of warehousing and manufacturing, the efficient movement of materials is crucial. Forklifts are a cornerstone of this process, providing a powerful means of transporting heavy loads. However, the introduction of accessories such as magnetic lifters has revolutionized the way materials, especially metal objects, are handled.

What is a Forklift Magnetic Lifter?

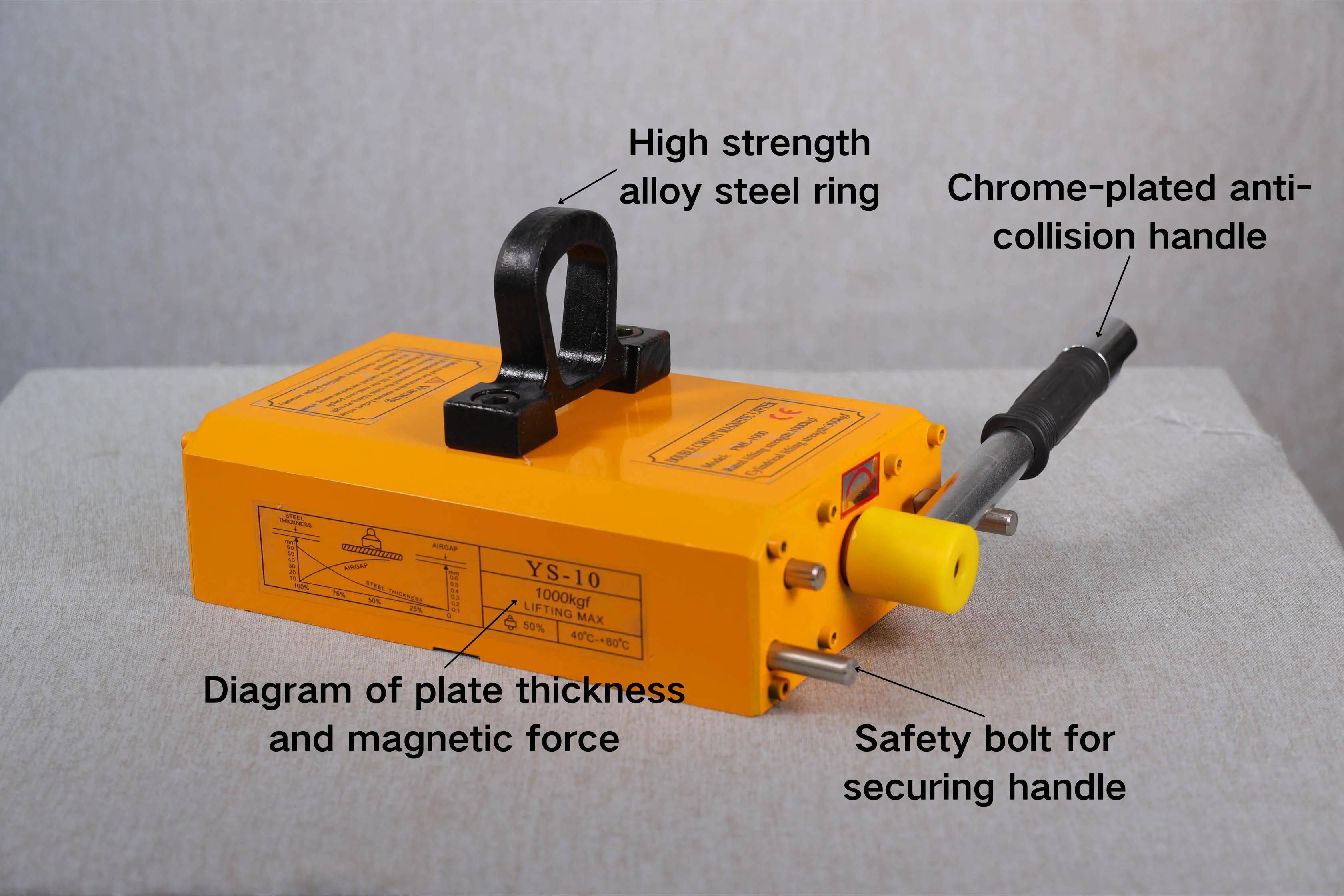

A forklift magnetic lifter is an attachment that can be mounted on the forks of a forklift. It consists of powerful magnets that can lift and transport ferromagnetic materials, such as steel plates and other iron-based products. These devices are designed with safety features to ensure that the load remains secure while in transit, making them an invaluable tool in many industrial settings.

Enhanced Efficiency and Safety

One of the most significant benefits of using a magnetic lifter is the increased efficiency in material handling. Traditional methods of lifting heavy metallic loads often require the use of slings, hooks, or chains, which can be time-consuming and complex. Magnetic lifters simplify this process by allowing operators to pick up and set down loads quickly and easily. This not only speeds up operations but also minimizes the risk of dropping or damaging valuable materials.

Safety is another vital aspect of using magnetic lifters. The devices are equipped with mechanisms to ensure that items remain secure while being lifted. This reduces the likelihood of accidents caused by dropped loads, which can pose significant hazards in busy warehouse environments. Magnetic lifters allow for quicker load handling, which in turn reduces the time that operators spend in potentially dangerous areas.

Versatility in Application

forklift magnetic lifter

Magnetic lifters are versatile and can be employed in various industries. Whether in manufacturing, construction, or shipping, these tools can be used to lift large sheets of metal, pipes, and even scrap materials. Their capability to handle loads of varying shapes and sizes makes them particularly appealing for companies that deal with different types of metal handling.

In addition, magnetic lifters can be adjusted to accommodate different sizes and weights of materials. Many models offer adjustable magnetic force to suit the specific needs of the task at hand. This adaptability further enhances their usability in a range of applications.

Considerations When Using Forklift Magnetic Lifters

While magnetic lifters provide numerous advantages, proper training and adherence to safety protocols are necessary for their effective operation. Operators must be familiar with the specifications of the lifter, including its weight capacity and the types of materials it can handle. Understanding the limitations of magnetic force is crucial to prevent accidents and ensure safe operation.

Moreover, the surface condition of the materials being handled plays a significant role in the effectiveness of magnetic lifters. Dirty or rusty surfaces can diminish the magnetic grip, leading to potential risks during lifting operations. Therefore, it's essential to maintain the cleanliness of loads to maximize safety and efficiency.

Conclusion

In conclusion, forklift magnetic lifters are a game-changing innovation in the realm of material handling. They enhance efficiency, improve safety, and offer versatility in application across various industries. As warehouses and manufacturing facilities continue to demand more efficient methods for transporting heavy loads, the adoption of magnetic lifters will likely increase.

Investing in quality magnetic lifters and training for operators can lead to significant improvements in productivity while maintaining a strong focus on workplace safety. As technology advances and the need for more efficient handling solutions grows, magnetic lifters are set to become even more integral to the successful operation of material handling environments. As such, they are not just an accessory but a vital component in the toolkit of modern industrial operations.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025