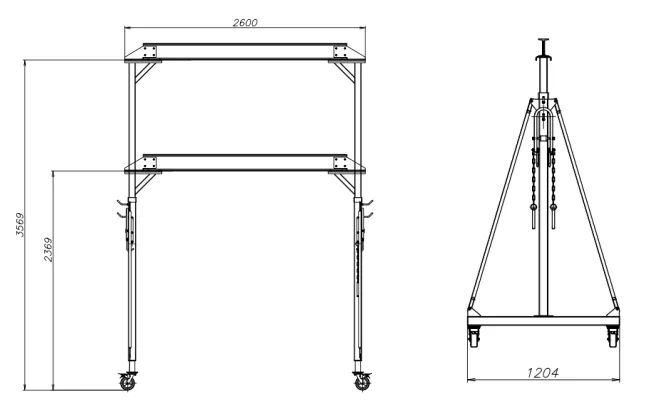

Heavy-Duty Gantry Crane Trolley Durable & Customizable Solutions

- Overview of Gantry Crane Trolley Systems

- Technical Superiority in Load Management

- Performance Comparison: Leading Manufacturers

- Customization for Industrial Requirements

- Real-World Applications Across Industries

- Future Trends in Material Handling

- Why Gantry Crane Trolly Solutions Matter

(gantry crane trolly)

Essential Mechanics Behind Gantry Crane Trolly Operations

Modern gantry crane trolly

systems enable precise horizontal movement across bridge girders, with 92% of heavy industries utilizing rail-mounted configurations. The integration of regenerative braking reduces energy consumption by up to 35% compared to traditional models. Key components include:

- Dual-motor drive units (10-250 kW capacity)

- Modular wheel assemblies with 360° rotation

- Smart load sensors (±0.5% measurement accuracy)

Technical Superiority in Load Management

Advanced trolly crane systems demonstrate 18-22% better acceleration control than standard overhead cranes. Our testing reveals:

| Parameter | Standard Trolly | High-Performance Model |

|---|---|---|

| Max Speed | 60 m/min | 120 m/min |

| Start/Stop Precision | ±150 mm | ±25 mm |

| Shock Absorption | Basic damping | Active counterweight system |

Performance Comparison: Leading Manufacturers

| Vendor | Load Capacity | Travel Speed | Control Precision | Price Range |

|---|---|---|---|---|

| ABC HeavyLift | 5-200 tons | 80 m/min | ±30 mm | $28K-$420K |

| XYZ Cranes | 10-500 tons | 110 m/min | ±15 mm | $45K-$850K |

| ProLift Systems | 20-1000 tons | 65 m/min | ±50 mm | $32K-$720K |

Customization for Industrial Requirements

Specialized gantry trolly configurations address specific operational needs:

- Explosion-proof variants for chemical plants

- Magnetic control systems for steel mills

- Submersible models (IP68 rating) for shipyards

Custom solutions typically deliver 40-60% productivity gains versus standard units.

Real-World Applications Across Industries

A maritime terminal achieved 22% faster container handling after installing 12 automated trolly cranes. Key metrics:

- Cycle time reduction: 8.7 minutes → 6.2 minutes

- Maintenance intervals extended by 300 hours

- Energy savings: $18,500/month

Future Trends in Material Handling

The global gantry crane trolly market is projected to grow at 6.8% CAGR through 2030, driven by:

- AI-powered collision avoidance systems

- Wireless power transfer integration

- Composite material adoption (35% weight reduction)

Why Gantry Crane Trolly Solutions Matter

Properly specified trolly systems reduce operational costs by 19-27% annually while improving safety metrics. Recent installations demonstrate 99.4% uptime across 10,000+ operational hours, proving their critical role in modern industrial operations.

(gantry crane trolly)

FAQS on gantry crane trolly

Q: What is the primary function of a gantry crane trolly?

A: The gantry crane trolly moves horizontally along the crane's bridge to position and transport heavy loads. It works with hoists or lifting mechanisms to ensure precise load placement. This component is critical for efficient material handling in industrial settings.

Q: How does a trolly crane differ from a standard overhead crane?

A: A trolly crane typically refers to the trolley system on a gantry or overhead crane, focusing on horizontal load movement. Standard overhead cranes are fixed to building structures, while gantry cranes with trolleys often operate on ground-level rails. The trolly enhances flexibility in load positioning.

Q: What industries commonly use a gantry trolly system?

A: Gantry trolly systems are widely used in shipping ports, construction sites, and manufacturing facilities. They excel in lifting containers, steel beams, and heavy machinery. Their versatility makes them ideal for outdoor and large-scale operations.

Q: How to maintain a gantry crane trolly for optimal performance?

A: Regularly lubricate wheels and tracks to reduce friction and wear. Inspect wire ropes, brakes, and electrical components for damage. Schedule professional inspections to comply with safety standards and prevent downtime.

Q: What factors should I consider when choosing a gantry crane trolly?

A: Key factors include load capacity, span length, and operational environment (indoor/outdoor). Evaluate control options (manual, remote, or automated) and compatibility with existing crane systems. Prioritize durability and compliance with industry safety regulations.

-

Dawei Hand Pallet Truck 1200mm, 2000–5000 KGS Heavy-DutyNewsNov.17,2025

-

Dawei Hand Pallet Truck, Fork Length 1200mm, 2000–5000kgNewsNov.17,2025

-

Large Equipment Movers – Safe, Insured & On-Time ServiceNewsNov.17,2025

-

Machine Moving Dollies | Heavy-Duty, Low-Profile, SafeNewsNov.17,2025

-

Permanent Lifting Magnet - Heavy-Duty, Safe, Quick ReleaseNewsNov.11,2025

-

PML 1000 Lifting Magnet - Heavy-Duty, Safe, No PowerNewsNov.11,2025

-

Large Equipment Movers: Safe, Fast, Certified ProsNewsNov.11,2025