Gantry Systems for Light-Duty Applications in Modern Industries

Understanding Light Duty Gantry Systems

In the realm of material handling and construction, light duty gantry systems have emerged as essential tools that facilitate the efficient movement and placement of materials and equipment. These versatile structures consist of a framework that supports a movable hoist or trolley, allowing for the lifting and transporting of loads in various work environments, such as warehouses, manufacturing plants, and construction sites. The following discusses the advantages, applications, and considerations associated with light duty gantry systems.

Advantages of Light Duty Gantry Systems

One of the primary benefits of light duty gantry systems is their portability. Unlike fixed overhead cranes, gantry systems can be easily disassembled and relocated, making them ideal for applications that require flexibility. This portability not only enhances their usability across different job sites but also allows organizations to optimize their workspace based on changing operational needs.

Additionally, light duty gantries are designed for lighter loads, typically ranging from a few hundred pounds to several tons. This characteristic makes them particularly well-suited for smaller projects where large cranes would be overkill. Their lightweight construction means they’re easier to move and position, and redundancy of equipment isn’t necessary for loads within the specified weight limits.

Cost-effectiveness is another significant advantage of light duty gantry systems

. They typically have lower initial purchase costs and maintenance expenses than larger, more complex lifting devices. This makes them an attractive option for small to medium-sized businesses that may not require heavy lifting solutions but still need the capability to efficiently move materials.Applications of Light Duty Gantry Systems

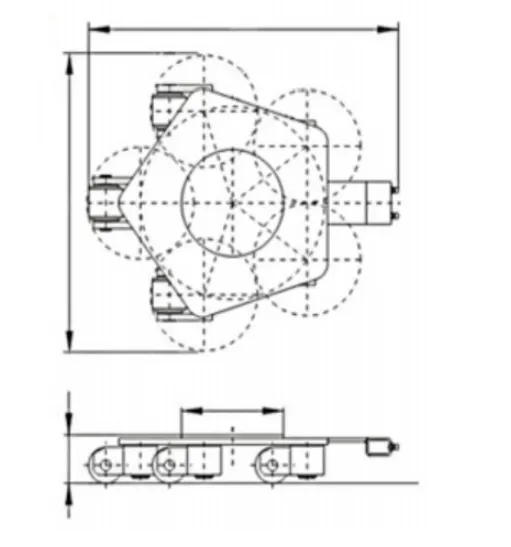

light duty gantry

Light duty gantry systems are employed across various industries, demonstrating their versatility and practicality. In manufacturing, they are commonly used on assembly lines to assist in the assembly or disassembly of machinery and equipment. The ability to adjust the height and location of the lifting apparatus enhances productivity, allowing workers to position materials precisely where needed.

In construction, gantry systems can be pivotal for moving lightweight building materials, tools, and equipment within a site. They help streamline operations and reduce the time and manpower required for transporting these items. Similarly, in the realm of maintenance and repair, these systems prove invaluable for lifting and maneuvering parts, such as engines or generators, in confined spaces where traditional lifting equipment may not fit.

Healthcare institutions leverage light duty gantry systems for transporting medical equipment, ensuring a smooth workflow without burdening staff. The entertainment industry also utilizes gantry systems for rigging and setting up lighting and sound equipment during events or performances.

Considerations When Utilizing Light Duty Gantry Systems

While light duty gantry systems offer many advantages, certain considerations are vital in their implementation. Weight capacity should be carefully evaluated to prevent accidents or injuries. Users must be trained in safety protocols to ensure the equipment is used correctly, as improper usage can lead to serious consequences.

Furthermore, regular maintenance is essential to prolong the system's lifespan and maintain operational efficiency. Periodic inspections help identify potential hazards or wear, ensuring that the equipment remains safe for use.

In conclusion, light duty gantry systems provide a flexible, cost-effective solution for businesses and industries requiring efficient material handling capabilities. Their portability, versatility, and ease of use make them invaluable tools in modern operations, capable of enhancing productivity while reducing manpower requirements. As industries continue to evolve, the role of these innovative lifting systems will undoubtedly expand, solidifying their place in the future of material handling.

-

Dawei Hand Pallet Truck 1200mm, 2000–5000 KGS Heavy-DutyNewsNov.17,2025

-

Dawei Hand Pallet Truck, Fork Length 1200mm, 2000–5000kgNewsNov.17,2025

-

Large Equipment Movers – Safe, Insured & On-Time ServiceNewsNov.17,2025

-

Machine Moving Dollies | Heavy-Duty, Low-Profile, SafeNewsNov.17,2025

-

Permanent Lifting Magnet - Heavy-Duty, Safe, Quick ReleaseNewsNov.11,2025

-

PML 1000 Lifting Magnet - Heavy-Duty, Safe, No PowerNewsNov.11,2025

-

Large Equipment Movers: Safe, Fast, Certified ProsNewsNov.11,2025