gantry crane and hoist

The Importance of Gantry Cranes and Hoists in Modern Industry

In the ever-evolving landscape of industry and manufacturing, the significance of efficient lifting equipment has become increasingly paramount. Among the various types of machinery designed to facilitate the movement of heavy materials, gantry cranes and hoists stand out as indispensable tools. Their unique designs and functionalities enable them to meet the rigorous demands of various industrial sectors, including construction, shipping, and manufacturing.

Understanding Gantry Cranes

Gantry cranes are large, bridge-like structures that consist of a horizontal beam supported on two or more vertical legs. These cranes can move along a set of tracks or wheels, allowing them to traverse large areas and lift heavy loads with ease. Typically, gantry cranes are used to transport materials within a defined space, making them ideal for warehouses, shipyards, and industrial manufacturing facilities. They can accommodate various lifting mechanisms, including electric hoists, which enhance their versatility.

One of the primary advantages of gantry cranes is their ability to handle enormous weights. These cranes can lift loads ranging from a few tons to several hundred tons, depending on their design and specifications. Their robust construction ensures that they can withstand the rigorous demands of everyday operations, making them a reliable choice for industries that require heavy lifting.

The Role of Hoists

Complementing the capabilities of gantry cranes are hoists, which serve as the lifting mechanisms used to raise and lower loads. Hoists come in various forms, including manual, electric, and pneumatic systems, each designed to cater to different application needs. Electric hoists, for instance, are commonly employed in environments where speed and efficiency are crucial, as they allow for quick lifting and lowering of loads with minimal manual intervention.

gantry crane and hoist

The integration of hoists with gantry cranes creates a powerful combination that optimizes operational efficiency. The hoist's ability to lift loads vertically, combined with the crane's lateral movement capabilities, significantly enhances the workflow within industrial settings. This synergy allows for the seamless transportation of materials from one location to another, minimizing downtime and maximizing productivity.

Safety Considerations

While gantry cranes and hoists are invaluable assets in industrial operations, safety remains a paramount concern. The lifting of heavy loads presents inherent risks, and it is crucial that operators are thoroughly trained and that equipment is regularly inspected and maintained. Implementing safety protocols, such as load testing, proper rigging techniques, and adherence to weight limits, is essential to mitigate accidents and ensure a safe working environment.

Additionally, incorporating safety features such as limit switches, emergency stop buttons, and load indicators can provide an extra layer of protection. These devices alert operators to potential hazards and help prevent equipment failure. Regular training and drills should also be conducted to ensure that all personnel are familiar with emergency procedures related to crane and hoist operations.

Conclusion

Gantry cranes and hoists play a vital role in modern industry, facilitating the efficient and safe movement of heavy materials. Their ability to handle large loads and traverse extensive spaces makes them invaluable in various applications, from manufacturing to construction. However, the combination of efficiency and safety must be prioritized to maximize their benefits. By investing in proper training, maintenance, and safety measures, industries can harness the full potential of gantry cranes and hoists while minimizing risks. As technology continues to advance, the evolution of these lifting systems is sure to enhance their capabilities further, solidifying their place as essential components in the industrial landscape.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

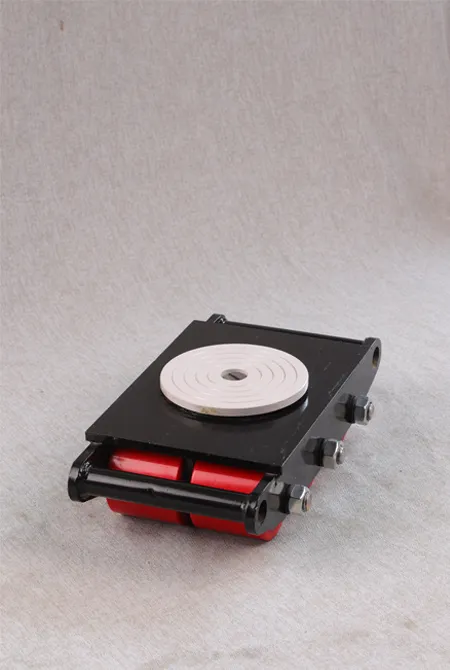

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025