Gantry Crane Systems and Hoisting Solutions for Efficient Material Handling

Gantry Crane and Hoist The Backbone of Heavy Lifting

In the industrial world, efficiency and safety in material handling are paramount. Among the various types of lifting equipment, gantry cranes and hoists stand out as essential tools that facilitate heavy lifting tasks in construction sites, warehouses, and manufacturing plants. Their versatile design and operational capabilities make them indispensable in a range of applications.

Understanding Gantry Cranes

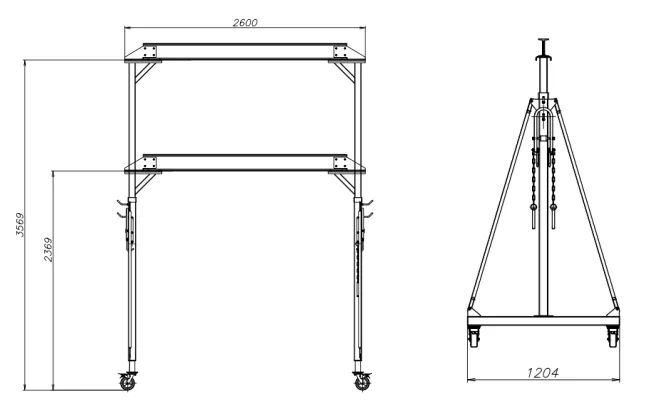

A gantry crane consists of a bridge that spans two or more supporting legs, which run on wheels or tracks to move the crane horizontally. This structure allows for the lifting and lowering of heavy loads with precision and ease. Gantry cranes come in various sizes and configurations, tailoring them to specific industrial needs, from small-scale workshops to large shipping yards.

One of the defining features of gantry cranes is their mobility. Unlike traditional overhead cranes, which are fixed in position, gantry cranes can be moved from one location to another. This characteristic makes them particularly useful in environments where versatility is needed. They can be manually operated or equipped with electric drives for ease of movement.

The Role of Hoists

Hoists are integral components of gantry cranes and serve as the mechanism for lifting loads. They can be powered by electric motors, hydraulic systems, or manual operations, enabling them to handle various weight capacities and lifting heights. The choice of hoist depends on the specific requirements of the task, including load weight, height of lift, and operational speed.

gantry crane and hoist

Electric hoists are commonly used in conjunction with gantry cranes due to their ability to lift heavy loads with minimal human effort. They often come equipped with safety features such as overload protection and emergency stop functions to ensure safe operations. Manual hoists, while requiring more physical effort, are still popular for tasks that involve lighter loads or in situations where electricity is unavailable.

Applications and Advantages

Gantry cranes and hoists are employed in a variety of industries, from manufacturing and construction to shipping and automotive repair. In manufacturing, they facilitate the movement of heavy machinery and components, increasing productivity and reducing the risk of workplace injuries. In construction, they are crucial for lifting beams, skylights, and prefabricated structures, contributing to the timely completion of projects.

The combination of a gantry crane and hoist offers several advantages. First, their modular design allows for customization according to the operational space and load requirements. Second, they enhance workplace safety by minimizing manual lifting, which is a significant cause of injuries in industrial settings. Third, their flexibility enables them to adapt to various tasks, making them a cost-effective investment.

Conclusion

In summary, gantry cranes and hoists are vital tools in the industrial landscape, enabling efficient and safe handling of heavy loads. Their mobility, customization options, and integration of advanced safety features ensure they meet the diverse demands of modern industries. As technology continues to evolve, we can expect even more innovations in gantry crane and hoist design, further enhancing their functionality and efficiency in material handling operations.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025