gantry crane construction

The Construction of Gantry Cranes An Overview

Gantry cranes are essential pieces of equipment in various industries, such as construction, shipping, and manufacturing. Characterized by their unique design, which consists of a framework resembling a gantry, these cranes are used to lift and maneuver heavy loads. Their construction entails several critical steps that ensure safety, efficiency, and durability.

Understanding the Gantry Crane Structure

Before delving into the construction process, it's important to understand the components of a gantry crane. A typical gantry crane consists of a horizontal beam supported by two vertical legs, which move on wheels along a track. The horizontal beam is equipped with a hoisting mechanism that can lift heavy loads vertically. The simplicity of the design belies the engineering precision required to ensure stability and functionality, especially when dealing with heavy weights.

Designing the Gantry Crane

The first step in the construction of a gantry crane is its design. Engineers must take into account the load capacity, operational environment, and intended use. Calculations regarding stress, load distribution, and material selection are crucial. Common materials used include steel due to its high strength-to-weight ratio. The design must also adhere to industry standards and safety regulations to prevent accidents during operation.

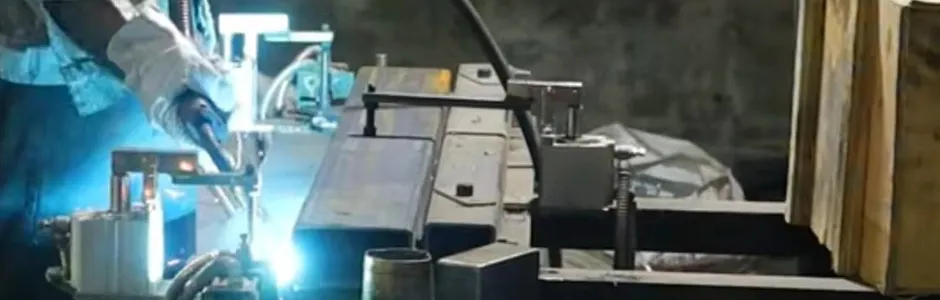

Fabrication of Components

Once the design is finalized, the next phase involves fabrication. This process includes cutting the steel sections to the required dimensions, welding, and assembling various components like the beams and legs. Advanced techniques such as CNC machining are often employed to ensure precision in manufacturing. Proper treatment of the metal, such as galvanization or painting, is also important to protect the crane from corrosion and wear over time.

gantry crane construction

Assembly

The assembly of a gantry crane typically takes place either on-site or in a dedicated assembly facility. During assembly, the vertical legs are securely bolted to the horizontal beam. Careful alignment is essential to ensure that the crane operates smoothly. At this stage, the hoisting mechanism, which could range from electric winches to chain hoists, is installed. This assembly process must be conducted with strict adherence to safety protocols, as improper assembly can lead to catastrophic failures when lifting heavy loads.

Installation and Testing

After assembly, the gantry crane must be installed at its designated location. This may involve using heavy-lift cranes or other equipment to place the gantry crane onto its tracks or foundations. Once installed, rigorous testing is conducted to ensure the crane operates within its specifications. Load tests simulate real operational conditions, verifying the crane's stability, responsiveness, and safety mechanisms.

Maintenance Considerations

The construction of gantry cranes does not end with installation. Regular maintenance is key to ensuring their longevity and safe operation. This includes routine inspections, lubrication of moving parts, and checking the electrical systems that power the hoists. Preventive maintenance can identify potential issues before they escalate, thereby reducing downtime and costs associated with repairs.

Conclusion

The construction of gantry cranes is a multifaceted process that combines engineering prowess, meticulous craftsmanship, and stringent safety measures. From initial design to installation and subsequent maintenance, every stage is critical to ensure that these cranes perform reliably in demanding environments. As industries continue to evolve, so too will the technologies and designs of gantry cranes, ensuring they remain vital in lifting and moving the heavy loads of tomorrow. By adhering to best practices in construction and maintenance, businesses can enhance operational efficiency and safety, ultimately leading to greater productivity.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025