gantry crane deutsch

Gantry Cranes An Overview

Gantry cranes are vital components of the material handling sector in various industries, including shipping, manufacturing, and construction. Characterized by their overhead structure supported by two or more legs, gantry cranes facilitate the movement of heavy loads across a workspace, making them indispensable for operations requiring efficiency and safety.

Design and Structure

A typical gantry crane consists of a bridge that spans the width of the workspace, supported by vertical legs at each end. These legs may roll on wheels or be fixed to a specific foundation, allowing them to handle loads in either fixed or mobile configurations. Gantry cranes can vary significantly in design; from small, portable units used in garages to massive structures capable of lifting tons in industrial settings. The materials used in their construction may include steel for strength and durability, often treated to resist corrosion.

Types of Gantry Cranes

Gantry cranes can be categorized primarily into two types full gantry cranes and semi-gantry cranes. Full gantry cranes have two legs that run on tracks, providing stability and the capability to cover large areas. Meanwhile, semi-gantry cranes possess one leg, which allows them to operate in environments where there isn't enough overhead space for a full gantry. These cranes are popular in warehouses and factory settings for their flexibility.

Additionally, portable gantry cranes have gained popularity for their lightweight design and mobility, allowing workers to easily move them from one location to another. They are often used for smaller tasks but can still lift substantial weights.

Uses in Various Industries

Gantry cranes are particularly prevalent in ports and shipyards, where they are used for loading and unloading cargo containers from ships. Their ability to lift heavy loads and transport them across vast distances greatly enhances operational efficiency. In the construction industry, gantry cranes make it possible to erect heavy structures and components with precision.

gantry crane deutsch

Moreover, in manufacturing environments, these cranes facilitate the assembly of large machinery and equipment, reducing labor costs and enhancing worker safety. The automotive industry also employs gantry cranes for tasks such as lifting engines and assembling vehicles on production lines.

Advantages

One of the main advantages of gantry cranes is their ability to operate in limited spaces. Compared to other lifting devices, gantry cranes require no overhead supports, making them ideal for warehouses with lower ceilings. They also offer increased safety when lifting heavy loads, as their design minimizes the risk of tipping or falling.

Additionally, gantry cranes can be customized to meet specific operational requirements. Features such as adjustable heights, spans, and lifting capacities can be tailored to match the needs of various projects.

Safety Features

Safety is a top priority when operating heavy machinery, and gantry cranes are designed with numerous safety features. These include limit switches to prevent overloads, emergency stop buttons, and safety locks on lifting mechanisms. Regular inspection and maintenance are also crucial to ensuring that the cranes operate safely and efficiently.

Conclusion

In summary, gantry cranes play a crucial role in modern industrial operations, providing versatile, efficient, and safe solutions for lifting and moving heavy loads. Their design allows for extensive adaptation to different use cases, making them a preferred choice across numerous industries. As technology advances, we can expect to see continued improvements in gantry crane design, enhancing their capabilities and operational efficiency. Overall, gantry cranes contribute significantly to improving productivity and safety within the workplace and will remain a cornerstone of industrial material handling for years to come.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

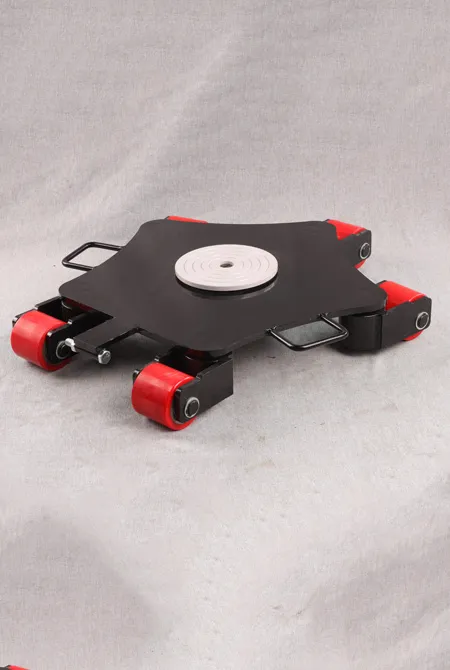

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025