Design and Analysis of Gantry Crane Girders for Industrial Applications

Understanding Gantry Crane Girders Design, Function, and Applications

In the realm of industrial machinery and material handling, gantry cranes stand out as vital equipment for lifting and transporting heavy loads. One of the critical components of a gantry crane is its girder, which plays an essential role in ensuring the crane's stability, strength, and functionality. This article explores the design, importance, and various applications of gantry crane girders.

What is a Gantry Crane Girder?

A gantry crane is a type of crane that features a bridge-like structure supported by two vertical posts, known as legs. The girders are horizontal beams that connect these posts and support the crane's hoisting mechanism. Typically made from high-strength steel or aluminum, girders are engineered to withstand the substantial forces during lifting operations. They not only support the weight of the loads being lifted but also the weight of the crane itself and any additional rigging equipment attached.

Design Considerations

When designing a gantry crane girder, several factors must be taken into account. First and foremost is the load capacity. The girder must be able to handle the maximum weight it is intended to lift as well as any dynamic forces that occur during operation. The material selection also plays a crucial role; materials need to strike a balance between being lightweight for ease of movement while providing sufficient strength to prevent deformation or failure under load.

Additionally, the dimensions of the girder are critical. They must be designed to minimize deflection during operation, ensuring that the path of the load remains stable and predictable. This often involves calculating the optimal width, height, and thickness of the girder. Furthermore, factors like span length, environmental conditions (such as exposure to corrosive substances or extreme weather), and required safety factors significantly influence the design process.

Importance of Gantry Crane Girders

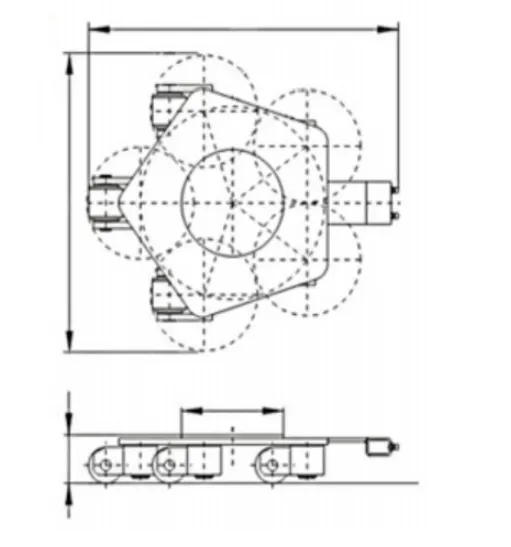

gantry crane girder

The girder is the backbone of a gantry crane; its integrity is crucial for safe operation. A well-engineered girder helps avoid structural failures, which could result in catastrophic accidents, property damage, and, most importantly, injuries to personnel. Regular inspections and maintenance of the girders are essential practices to ensure that they remain in top condition over the years.

Moreover, the design and construction of the girder can have economic implications. A more efficient design can reduce material costs and weight, which makes the crane easier to transport and set up. Furthermore, a well-designed girder could increase the crane's lifespan and decrease the frequency of repairs and maintenance.

Applications

Gantry cranes and their girders are used across various industries. In manufacturing, they are instrumental in moving heavy components during assembly processes. In shipping yards, they assist in loading and unloading containers from ships, while in construction, they are used to lift steel beams and scaffolding materials. Additionally, in warehouses, these cranes can streamline operations by moving products from one location to another efficiently.

Furthermore, special designs of gantry cranes can be deployed in unconventional settings; for example, they can be adjusted to accommodate various heights and spans depending on the workspace. Some designs even allow for mobility, enabling the crane to traverse large areas as opposed to being stationary.

Conclusion

In conclusion, gantry crane girders are fundamental elements of this versatile lifting equipment. Their design must prioritize safety, strength, and efficiency to support various industrial operations effectively. As industries continue to evolve, the innovation in gantry crane designs and materials will likely advance, enhancing their functionality and expanding their applications even further. Understanding the role of girders not only underscores their importance but also highlights the engineering ingenuity involved in creating reliable lifting solutions that keep modern industries operating smoothly.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025