Jan . 13, 2025 11:47

Back to list

gantry crane system

The gantry crane system has emerged as a pivotal component for industries requiring heavy-duty lifting solutions. With its versatility, efficiency, and robust construction, this equipment has redefined operational dynamics across various sectors such as construction, shipping, and manufacturing. Integrating a gantry crane into your workflow can significantly enhance productivity, reduce human error, and ensure the safety of your workforce, standing as a testament to modern engineering marvels.

Expertise in maintenance and operation is critical to maximizing the lifespan and efficiency of gantry cranes. Regular inspections and compliance with safety regulations are essential practices. Industry experts recommend implementing a comprehensive maintenance schedule that not only adheres to manufacturer guidelines but also addresses specific operational conditions and challenges. This proactive approach ensures that the equipment remains in optimal condition, thereby preventing unexpected breakdowns and costly repairs. Trust in gantry crane systems also stems from their track record. Case studies from leading businesses provide compelling evidence of how these systems have revolutionized operations. For instance, a notable global shipping company reported a 40% increase in cargo handling efficiency after installing state-of-the-art gantry cranes. This transformation underscores not only the operational benefits but also the environmental impact savings through reduced energy consumption and lowered emissions. In conclusion, the gantry crane system is not merely a tool but a strategic asset that embodies reliability, innovation, and efficiency. By understanding and leveraging the full potential of this equipment, industries can not only enhance their operational prowess but also solidify their status as forward-thinking leaders in their respective fields. This aligns perfectly with modern business goals of sustainability, efficiency, and profitability, affirming the gantry crane system as an investment in future success.

Expertise in maintenance and operation is critical to maximizing the lifespan and efficiency of gantry cranes. Regular inspections and compliance with safety regulations are essential practices. Industry experts recommend implementing a comprehensive maintenance schedule that not only adheres to manufacturer guidelines but also addresses specific operational conditions and challenges. This proactive approach ensures that the equipment remains in optimal condition, thereby preventing unexpected breakdowns and costly repairs. Trust in gantry crane systems also stems from their track record. Case studies from leading businesses provide compelling evidence of how these systems have revolutionized operations. For instance, a notable global shipping company reported a 40% increase in cargo handling efficiency after installing state-of-the-art gantry cranes. This transformation underscores not only the operational benefits but also the environmental impact savings through reduced energy consumption and lowered emissions. In conclusion, the gantry crane system is not merely a tool but a strategic asset that embodies reliability, innovation, and efficiency. By understanding and leveraging the full potential of this equipment, industries can not only enhance their operational prowess but also solidify their status as forward-thinking leaders in their respective fields. This aligns perfectly with modern business goals of sustainability, efficiency, and profitability, affirming the gantry crane system as an investment in future success.

Latest news

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

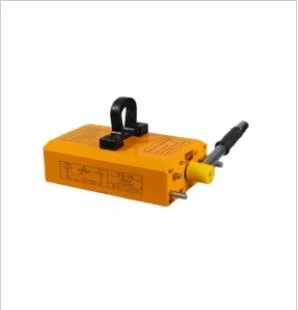

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025