gantry crane system

Gantry Crane System An Overview

A gantry crane system is an intricate piece of engineering equipment designed to lift and move heavy loads in manufacturing, construction, and shipping environments. Characterized by its bridge-like structure supported by vertical legs, the gantry crane operates efficiently over a specified area, providing versatile solutions for material handling tasks.

Design and Structure

The fundamental design of a gantry crane system consists of a horizontal beam, known as the gantry, that spans between two vertical supports, or legs. This structure allows for the crane to straddle the object being lifted, thereby offering enhanced stability and support. The gantry crane can be fixed or portable, depending on the requirements of the operational space.

Materials used in the construction of gantry cranes typically include high-strength steel to ensure durability and resistance to the heavy loads they will bear. The crane can be equipped with a variety of lifting mechanisms, including hoists, winches, and blocks, depending on the specific use case. Some advanced models also incorporate automation features, allowing for remote operation and improved precision in material handling.

Applications

Gantry cranes are immensely versatile and find applications across several industries. In manufacturing, they are commonly used for moving large parts or assemblies, such as automotive components or machinery. In construction, gantry cranes facilitate the lifting of heavy materials, like steel beams and concrete blocks, significantly increasing efficiency on job sites.

Warehouse operations also benefit greatly from gantry cranes, where they are used for loading and unloading goods from trucks or shipping containers. Their ability to traverse large open spaces makes them ideal for reaching loads that might otherwise be difficult to access with traditional forklifts or other lifting devices.

Advantages

gantry crane system

One of the primary advantages of a gantry crane system is its ability to operate in confined spaces where conventional cranes might not be feasible. Their adjustable height and width provide flexibility, making them suitable for various tasks. Additionally, gantry cranes do not require extensive installation work like overhead cranes, allowing for quicker deployment and less disruption to ongoing operations.

Moreover, gantry cranes can be designed to carry a wide range of weights, from small components to several tons, enhancing their utility in various settings. The ease of use, coupled with minimal maintenance requirements, further solidifies their position as essential equipment in many industries.

Safety Considerations

While gantry cranes offer numerous benefits, safety remains a top priority when operating such heavy machinery. Operators must be trained to understand the weight limits of the crane and the proper techniques for securing loads before lifting. Regular maintenance checks are crucial to ensure all components of the crane are functioning properly, minimizing the risk of accidents or equipment failure.

Implementing safety features such as overload protection systems, limit switches, and emergency stop buttons can greatly enhance operational safety. Moreover, clearly marked pathways and communication protocols must be established to avoid hazards during operation, especially in busy work environments.

Future Trends

As technology continues to evolve, the gantry crane system is also witnessing advancements. The integration of smart technologies, such as IoT sensors and AI, is transforming how these cranes operate. Smart gantry cranes can monitor load weights, predict maintenance needs, and enhance operational efficiency through data analytics. The trend towards automation in logistics and manufacturing further supports the growing adoption of advanced gantry systems.

In conclusion, the gantry crane system is a critical component in modern industrial operations. Its versatility, efficiency, and reliability make it an invaluable asset in various applications, from construction sites to manufacturing facilities. As technology and safety standards continue to evolve, the future of gantry cranes promises enhanced capabilities and increased operational safety, ensuring they remain at the forefront of material handling solutions.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

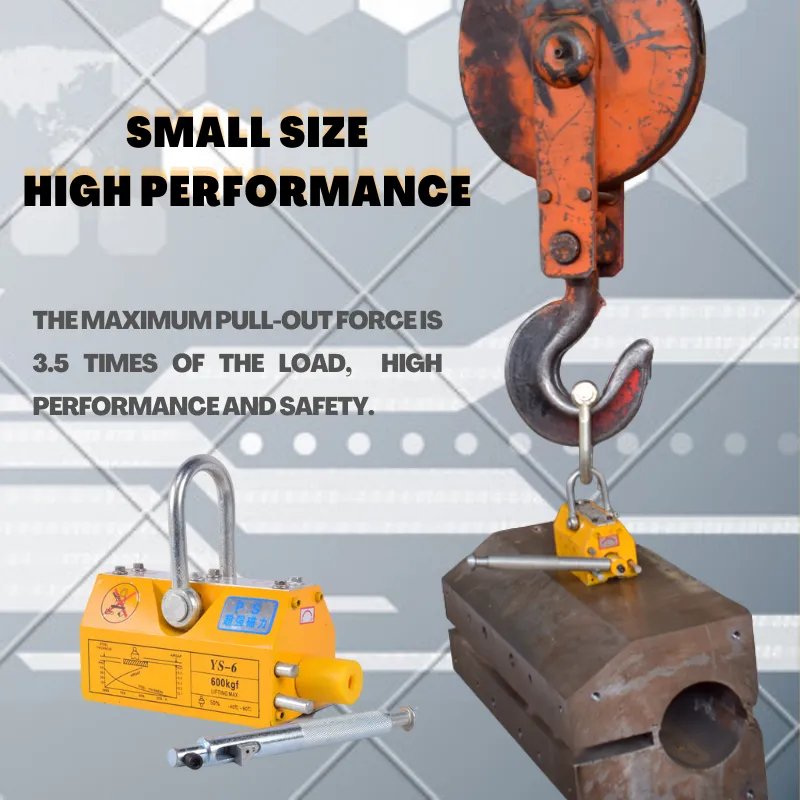

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025