Gantry Systems and Their Impact on Modern Industrial Automation and Efficiency

Understanding Gantry Equipment Advancements and Applications

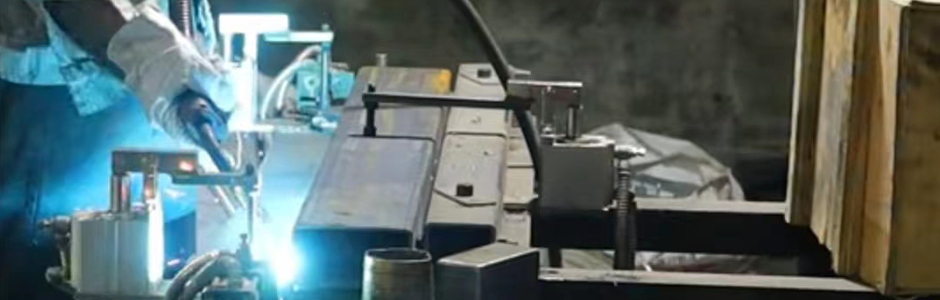

Gantry equipment plays a critical role in various industries, serving as essential tools that enhance efficiency and safety during lifting and transportation operations. The term “gantry” refers to a structure that supports equipment used to lift or move materials and products across horizontal distances, typically mounted on rails or wheels. These systems can be found in sectors such as manufacturing, construction, shipping, and even in healthcare, demonstrating their versatility and functionality.

One of the most common forms of gantry equipment is the gantry crane. These cranes are designed to lift heavy loads and have a bridge-like structure that spans across a workspace. Gantry cranes are equipped with hoists that can move vertically, allowing them to pick up heavy materials and transport them with ease. Their design enables them to operate in areas where traditional cranes may not fit, making them indispensable in tight or confined spaces. Various sizes of gantry cranes are available, from small portable versions for light loads to enormous cranes capable of lifting tons in shipyards and warehouses.

The advancements in technology have significantly improved the design and functionality of gantry equipment. Modern gantry systems are now equipped with smart technologies, such as sensors and automation features, which enhance operational safety and efficiency. For instance, load sensors can detect the weight of the materials being lifted, allowing for precise adjustments and preventing overloading. Additionally, increasingly sophisticated controls enable operators to manage multiple gantries simultaneously, streamlining operations and reducing time spent on manual handling.

Moreover, the rise of electric and battery-operated gantry cranes marks a significant shift towards more sustainable operations. These electric models offer lower emissions compared to their diesel counterparts and are quieter, making them suitable for indoor applications in settings like warehouses or manufacturing plants. As industries become more environmentally conscious, the demand for such eco-friendly equipment continues to rise.

gantry equipment

In terms of applications, gantry equipment is widely utilized in various fields

. In the shipping industry, gantry cranes are crucial for loading and unloading cargo containers from ships, maximizing efficiency at busy ports. Their ability to operate at great heights and reach across large vessels makes them ideal for handling heavy loads in a limited timeframe. In construction, gantry systems are vital for moving materials such as steel beams or precast concrete panels, reducing the risk of injury associated with manual lifting.In the healthcare sector, specialized gantry equipment is employed in medical imaging technologies, such as MRI and CT scanners. The gantry in these machines is the supportive structure that houses the imaging equipment, enabling the precise positioning of patients during diagnostic procedures. Such applications illustrate how gantry technology transcends traditional industrial roles, contributing significantly to advancements in fields impacting daily life.

Despite the many advantages gantry equipment offers, operators must adhere to strict safety protocols to mitigate risks associated with lifting heavy loads. Regular maintenance, proper training, and adherence to operating limits are crucial to ensuring safe operations. Furthermore, advancements in operator training—through virtual reality simulations and other innovative methodologies—are being deployed to prepare workers for effective and safe equipment use.

In conclusion, gantry equipment stands as a testament to engineering innovation across multiple industries. Its ability to improve efficiency while enhancing safety continues to make it a vital component in lifting and moving applications. As technology evolves, so too will the capabilities and implementations of gantry systems, ensuring they remain pivotal in the operational landscape.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025