gantry girder crane

Understanding Gantry Girder Cranes Key Features and Applications

Gantry girder cranes are crucial pieces of equipment in modern industrial and construction settings. Their unique design and functionality make them indispensable for handling heavy loads, facilitating effective material handling processes across various environments. This article delves into the fundamental features, advantages, and applications of gantry girder cranes, highlighting their significance in enhancing operational efficiencies.

What is a Gantry Girder Crane?

A gantry girder crane consists of a hoist mechanism supported by a framework of girders and legs that form a bridge-like structure. This crane operates on a set of rails, providing lateral movement alongside its vertical lifting capabilities. Unlike traditional overhead cranes, gantry cranes are often more versatile and can be used in outdoor and indoor settings depending on the specific design configurations.

Key Features

1. Structural Composition The primary components of a gantry girder crane include the main girders, which support the hoist mechanism, and the legs that provide stability and mobility. They can be made from steel or aluminum, depending on the weight capacities required.

2. Mobility One of the defining features of gantry girder cranes is their mobility. Many models are equipped with wheels that allow for easy movement from one location to another, making them suitable for tasks that require flexibility.

3. Versatile Hoisting Mechanism Typically equipped with electric or manual hoists, these cranes can lift and lower various loads, making them highly adaptable for different projects.

4. Adjustable Height and Span Gantry cranes often come with adjustable height options, allowing users to modify the crane's elevation to fit specific lifting requirements. The span of the beam can also be customized to accommodate different load sizes.

Advantages of Gantry Girder Cranes

gantry girder crane

1. Cost-Effective Solution Gantry cranes are generally more affordable than fixed overhead cranes, especially when it comes to installation and maintenance. Their modular design allows for easy assembly and disassembly, further reducing costs.

2. Space Efficiency With their ability to operate both indoors and outdoors, gantry cranes are suitable for use in a variety of terrains. Their design minimizes the space needed for operation, enabling efficient use of available workspace.

3. Safety Features Modern gantry cranes often include safety mechanisms such as overload protection systems and emergency stop buttons, enhancing the safety of operators and minimizing the risk of accidents.

4. Customizable Designs Different industries have varying lifting needs, and gantry cranes can be customized in terms of size, load capacity, and features to meet specific requirements. This adaptability makes them appealing across multiple sectors.

Applications Across Industries

Gantry girder cranes serve a wide array of industries, each finding unique applications for this versatile equipment

- Manufacturing In factories, gantry cranes are commonly used for assembling parts, moving raw materials, and transferring finished products to storage. - Construction They play a vital role in lifting heavy construction materials and equipment, facilitating safe and efficient building processes. - Shipping and Logistics In ports and warehouses, gantry cranes are used to load and unload containers, improving the speed and efficiency of logistics operations. - Maintenance and Repair These cranes are invaluable in maintenance scenarios where heavy machinery or equipment needs to be lifted for repairs or inspections.

Conclusion

In conclusion, gantry girder cranes are integral to modern industrial operations, offering practicality, flexibility, and efficiency in material handling. With their robust design and customizable capabilities, they cater to diverse applications across various sectors, making them an asset to any business that requires heavy lifting solutions. Understanding the features and advantages of these cranes helps industries leverage their potential to optimize processes and enhance productivity.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

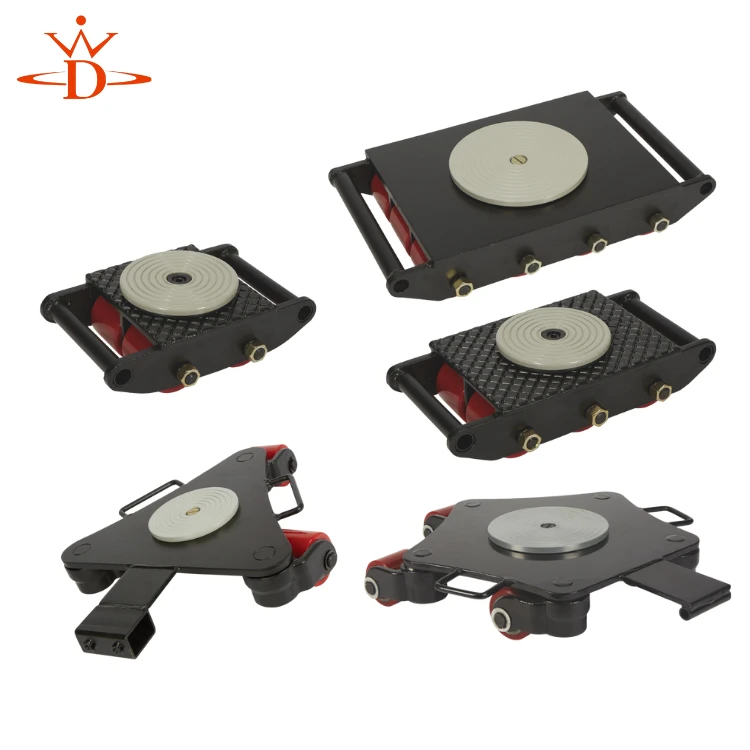

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025