Versatile Lifting Solutions for Efficient Gantry Systems in Various Industries

Gantry Lifting Equipment Revolutionizing Material Handling

In the modern industrial landscape, efficiency and safety in material handling are paramount. Among the various solutions available, gantry lifting equipment has emerged as a versatile and indispensable tool for many industries. This equipment not only enhances productivity but also ensures compliance with safety standards, making it a critical investment for businesses engaged in manufacturing, construction, and shipping.

Understanding Gantry Lifting Equipment

Gantry lifting equipment typically consists of a framework with a platform or a hoist that facilitates the movement of heavy objects. The design often includes vertical supports, horizontal beams, and wheels that allow the gantry to traverse along a predetermined path. This mobile aspect distinguishes gantry systems from fixed lifting solutions, providing greater flexibility in handling materials across various workspaces.

Gantry systems can be categorized into two broad types adjustable and fixed-height. Adjustable gantry cranes cater to operations requiring variable lifting heights, while fixed-height options are best suited for environments with standard load sizes. Most systems accommodate different lifting capacities, ranging from light-duty models capable of lifting a few hundred pounds to robust industrial versions that can manage several tons.

Advantages of Gantry Lifting Equipment

1. Versatility One of the standout features of gantry lifting equipment is its versatility. It can be utilized in various sectors, including manufacturing, shipping, automotive, and construction. Whether lifting engines, shipping containers, or heavy machinery parts, gantries offer a reliable solution tailored to specific needs.

2. Mobility The casters or wheels attached to the legs allow for easy movement across work sites. This mobility enables operators to position the gantry exactly where it is needed, reducing downtime and improving workflow efficiency.

gantry lifting equipment

3. Cost-Effectiveness Compared to permanent overhead cranes, gantry systems are often more economical. They require minimal installation and can be allocated to multiple sites, offering businesses the flexibility to adapt to changing project requirements without significant investment.

4. Ease of Use Most gantry lifting equipment is designed to be user-friendly, facilitating quick assembly and disassembly. Operators can set up the system with minimal training, allowing businesses to maximize their human resources effectively.

5. Safety Modern gantry systems are designed with safety in mind. Features such as weight limits, stability bars, and emergency stop buttons empower operators to manage heavy loads securely. Regular inspections and adherence to safety regulations further mitigate the risk of accidents on the job site.

Applications of Gantry Lifting Equipment

Gantry cranes play a crucial role in various applications. In manufacturing, they facilitate the assembly of machinery components and the lifting of large items during production processes. In shipping, gantry systems assist in loading and unloading containers from ships, ensuring smooth logistics operations. In the automotive industry, they are invaluable for lifting heavy engines and parts during assembly or repair.

Conclusion

As industries continue to evolve and face new challenges, the importance of efficient material handling solutions cannot be overstated. Gantry lifting equipment stands out as a adaptable and effective choice for businesses seeking to streamline operations while ensuring safety. With their versatility, mobility, cost-effectiveness, and ease of use, gantry systems are not just tools; they are vital components that can significantly enhance productivity and operational efficiency.

Investing in gantry lifting equipment is a step towards modernizing industrial processes, making workplaces safer, and ultimately driving business success. As the demand for efficient and flexible lifting solutions grows, gantry systems are positioned to remain a cornerstone in the toolkit of industries worldwide, transforming the way materials are handled and paving the way for a more dynamic and productive future.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

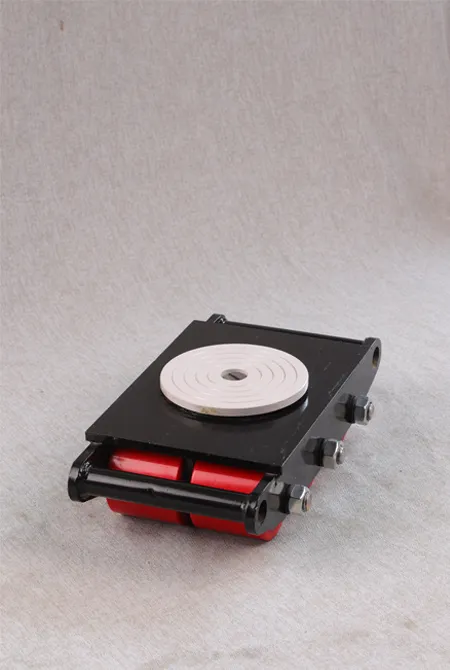

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025