Jan . 16, 2025 03:26

Back to list

2000 lb gantry crane

Gantry style cranes have become an indispensable asset in various industries due to their unparalleled flexibility, strength, and adaptability. Designed to handle heavy loads with precision and ease, these cranes are a crucial component in streamlining operations across sectors like construction, shipping, and manufacturing.

Beyond technical specifications, the trustworthiness of gantry style cranes is evident through testimonials of satisfied customers who have witnessed remarkable performance improvements after adopting these cranes. Accounts from large-scale projects consistently report decreased downtimes and increased operational fluidity, further endorsing the crane’s status as a backbone of industrial productivity. To make an informed purchase, potential buyers should consider factors such as load capacity, span, hoisting capabilities, and mobility options, as these will impact the crane's suitability for specific tasks. Partnering with reputable manufacturers or suppliers that have a proven track record in the crane industry is also advisable to ensure access to reliable after-sales support and maintenance services. Emphasizing innovation, current developments in gantry style crane technology focus on energy efficiency and sustainability. Electric and hybrid models are becoming increasingly popular, offering a quieter, more eco-friendly option that reduces the carbon footprint of large industrial sites. These advancements are rapidly gaining traction as industries aim to balance operational efficiency with environmental responsibility. In conclusion, gantry style cranes continue to play a pivotal role by blending strength, precision, and versatility in handling complex tasks. With progressive enhancements and adaptive functions, they remain a cornerstone of industrial operations, consistently delivering on promises of reliability and efficiency. Their ongoing evolution aligns with modern industries' shifting needs, underscoring their importance in today's competitive landscape.

Beyond technical specifications, the trustworthiness of gantry style cranes is evident through testimonials of satisfied customers who have witnessed remarkable performance improvements after adopting these cranes. Accounts from large-scale projects consistently report decreased downtimes and increased operational fluidity, further endorsing the crane’s status as a backbone of industrial productivity. To make an informed purchase, potential buyers should consider factors such as load capacity, span, hoisting capabilities, and mobility options, as these will impact the crane's suitability for specific tasks. Partnering with reputable manufacturers or suppliers that have a proven track record in the crane industry is also advisable to ensure access to reliable after-sales support and maintenance services. Emphasizing innovation, current developments in gantry style crane technology focus on energy efficiency and sustainability. Electric and hybrid models are becoming increasingly popular, offering a quieter, more eco-friendly option that reduces the carbon footprint of large industrial sites. These advancements are rapidly gaining traction as industries aim to balance operational efficiency with environmental responsibility. In conclusion, gantry style cranes continue to play a pivotal role by blending strength, precision, and versatility in handling complex tasks. With progressive enhancements and adaptive functions, they remain a cornerstone of industrial operations, consistently delivering on promises of reliability and efficiency. Their ongoing evolution aligns with modern industries' shifting needs, underscoring their importance in today's competitive landscape.

Next:

Latest news

-

The Ultimate Guide to Heavy Machinery Moving EquipmentNewsAug.04,2025

-

The Evolution of Large Equipment MoversNewsAug.04,2025

-

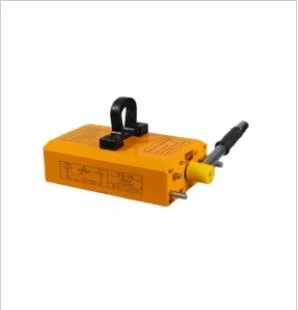

Maximizing Efficiency with PML Magnetic Lifters in Industrial OperationsNewsAug.04,2025

-

Choosing the Best Small Gantry CraneNewsAug.04,2025

-

Innovations in Permanent Lifting Magnet TechnologyNewsAug.04,2025

-

How to Maintain Your Adjustable Gantry Crane for LongevityNewsAug.04,2025

-

PML 6 Lifting Magnet Troubleshooting GuideNewsJul.25,2025