hand lifting magnets

Understanding Hand Lifting Magnets A Comprehensive Guide

Hand lifting magnets, also known as lifting magnets or permanent lifting magnets, are versatile tools that play a crucial role in various industrial and construction applications. These devices provide an effective and efficient means of handling heavy ferromagnetic materials, such as steel plates, pipes, and other metal components, without the need for cumbersome machinery. In this article, we will delve into the functionality, advantages, applications, and safety considerations associated with hand lifting magnets.

How Hand Lifting Magnets Work

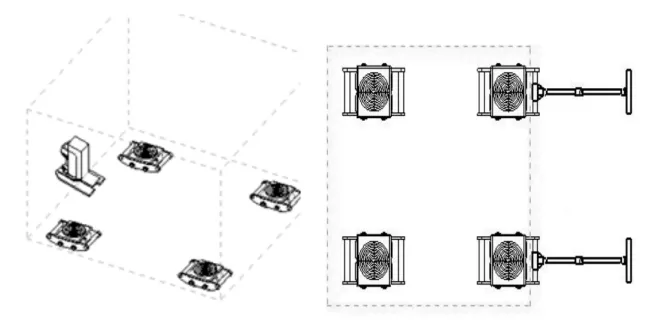

Hand lifting magnets operate on the principles of magnetism. These devices use permanent magnets to create a strong magnetic field that can lift metallic objects. A typical hand lifting magnet consists of a magnetic body and a handle. The magnet's body consists of materials with high magnetic permeability, which helps concentrate the magnetic field and increase lifting power.

When a user activates the handle, the mechanism either engages or disengages the magnetic flux. This design allows operators to easily control the lifting process. The lifting capacity of hand lifting magnets varies based on factors such as the size of the magnet, the type of magnet used, and the surface area of the object being lifted. Most hand lifting magnets are designed to lift weights ranging from a few hundred pounds to several tons.

Advantages of Hand Lifting Magnets

1. Efficiency and Speed Hand lifting magnets significantly reduce the time and effort required to move heavy materials. Traditional methods, such as using chains or straps, can be labor-intensive and time-consuming. In contrast, lifting magnets enable quick attachment and release.

2. Enhanced Safety By using hand lifting magnets, workers can minimize the risk of injury associated with manual lifting. The use of magnets helps in distributing the weight evenly, thus reducing strain on the body and preventing accidents.

3. Versatility These magnets can be used in various industries, including construction, manufacturing, automotive, and logistics. They are effective for lifting materials of different sizes and shapes, making them ideal for diverse applications.

4. Durability Most hand lifting magnets are built with robust materials that withstand harsh working environments. Their simple design ensures low maintenance, contributing to their long lifespan.

5. Cost-Effective While the initial investment in hand lifting magnets may seem significant, the long-term savings in labor costs and increased productivity often outweigh these expenses.

hand lifting magnets

Applications of Hand Lifting Magnets

Hand lifting magnets are employed in a wide range of applications, including

- Construction In construction, these magnets assist in lifting and positioning steel beams, girders, and other heavy components, streamlining operations and enhancing site safety.

- Manufacturing Factories utilize lifting magnets for handling sheet metal, coils, and other materials during assembly and production processes, enhancing efficiency on the shop floor.

- Metal Recycling Recycling centers use hand lifting magnets to sort and transport scrap metal, making the recycling process more efficient and environmentally friendly.

- Shipbuilding In the shipbuilding industry, lifting magnets facilitate the movement of heavy metal components, simplifying assembly and construction procedures.

Safety Considerations

Despite their numerous advantages, using hand lifting magnets comes with safety considerations. Operators must ensure that the lifting magnets are suitable for the weight and type of material being handled. It's essential to follow manufacturer guidelines regarding load capacities and operating procedures.

Regular inspections of the magnets should be conducted to check for wear and tear, as any damage could compromise lifting integrity. Workers should also receive proper training to understand how to operate lifting magnets safely and effectively.

Conclusion

Hand lifting magnets are invaluable tools in modern industry, providing a blend of efficiency, safety, and versatility. By understanding their functionality, advantages, applications, and safety measures, operators can maximize the benefits of these devices. Whether in construction, manufacturing, or recycling, hand lifting magnets enhance productivity while ensuring a safer work environment. As industries continue to evolve, the importance of these tools will undoubtedly grow, making them a staple in the handling of heavy materials.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025