Robust Gantry Crane Solutions for Heavy-Duty Industrial Applications and Lifting Needs

Understanding Heavy Duty Gantry Cranes

Heavy duty gantry cranes are essential equipment used in various industries where heavy lifting and precise movement of materials is required. Designed to handle substantial loads, these cranes are especially prevalent in shipping yards, construction sites, and heavy manufacturing facilities. This article delves into the components, benefits, applications, and factors to consider when selecting a heavy duty gantry crane.

Components of Heavy Duty Gantry Cranes

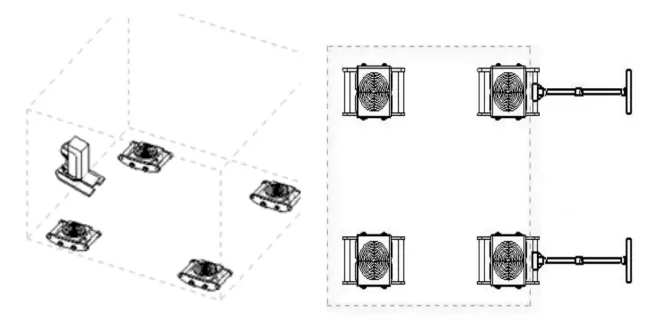

A heavy duty gantry crane typically consists of the following components 1. Gantry Structure The primary framework, which includes two vertical legs connected by a horizontal beam. This design allows the crane to straddle the load, facilitating movement across a work area. 2. Hoisting Mechanism This is responsible for lifting and lowering the load. It can employ electric or hydraulic systems, depending on the crane's specifications and the weight of the items being moved. 3. Travelling Mechanism The ability to move horizontally is crucial. Many gantry cranes feature wheeled legs that can be manually or motorized to traverse along a set path, providing flexibility in load positioning. 4. Control Systems Modern gantry cranes often include advanced control systems that offer precision and ease of use, integrating features like remote controls or automated systems for enhanced safety.

Benefits of Heavy Duty Gantry Cranes

The advantages of utilizing heavy duty gantry cranes in industrial settings are substantial - Versatility Gantry cranes can be configured for different applications, supporting various industries, from shipping to manufacturing. Their adjustable height and width allow for customization to meet specific needs. - Cost-Effective Compared to other lifting equipment, gantry cranes tend to be more economical for heavy lifting tasks. Their robust construction and durability mean they can handle large loads over extended periods without frequent need for maintenance. - Safety These cranes are designed with numerous safety features, such as overload protection and emergency stop buttons, ensuring that operators can move heavy items safely. Additionally, the clear visual paths enhance safety for workers nearby.

heavy duty gantry crane

Applications

Heavy duty gantry cranes have a myriad of applications - Construction They are used for lifting construction materials, equipment, and prefabricated structures, making the building process more efficient. - Shipping In ports, they facilitate the loading and unloading of shipping containers, drastically speeding up logistics operations. - Manufacturing These cranes are instrumental in moving heavy components within manufacturing plants, streamlining production lines.

Selecting the Right Heavy Duty Gantry Crane

When choosing a heavy duty gantry crane, several factors must be considered - Load Capacity Assess the maximum load that the crane will be required to lift and ensure the model chosen can handle it comfortably. - Span and Height Measure the workspace to determine the appropriate span (distance between legs) and height needed for the crane’s operation. - Mobility Requirements Consider whether a fixed or mobile crane is ideal for the workspace. Mobile gantry cranes offer flexibility, whereas fixed cranes provide stability. - Power Source Decide between electric, hydraulic, or manual systems based on the operational needs and available resources.

In conclusion, heavy duty gantry cranes play a pivotal role in modern industrial operations. Their robust design, versatility, and safety features make them indispensable tools in environments where heavy lifting is a daily necessity. By understanding their components, benefits, applications, and selection criteria, businesses can optimize their operations and ensure efficient material handling.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025