heavy duty machine dolly

The Utility and Versatility of Heavy-Duty Machine Dollies

In the world of logistics, manufacturing, and warehousing, heavy-duty machine dollies play an essential role in the efficient movement of heavy equipment and machinery. These robust tools are designed to facilitate the transportation of items that would otherwise be cumbersome or impossible to move without specialized equipment. Understanding the utility and versatility of heavy-duty machine dollies can help businesses optimize their operations and improve safety standards in their work environments.

What is a Heavy-Duty Machine Dolly?

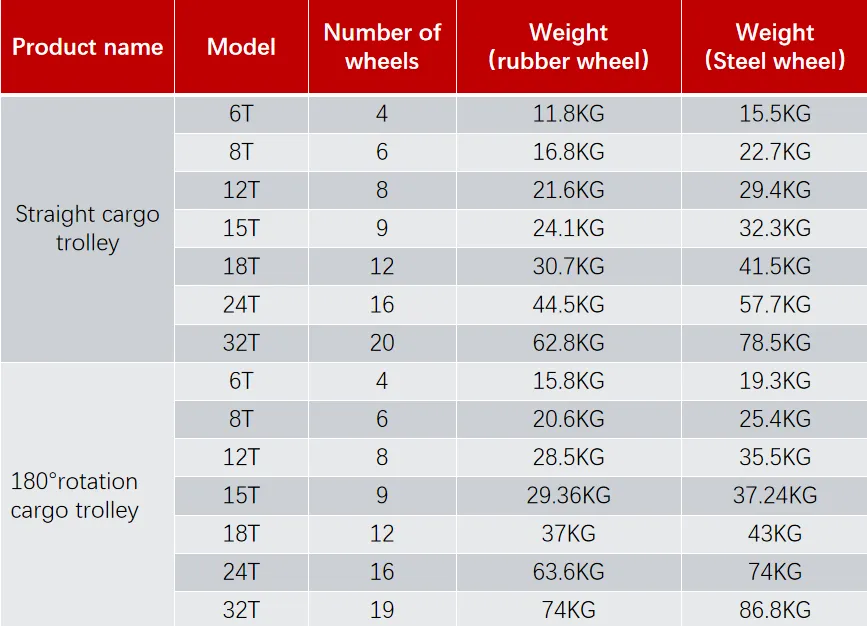

A heavy-duty machine dolly is a wheeled platform engineered to support and move substantial loads, typically ranging from several hundred to several thousand pounds. Made of durable materials such as steel or reinforced composite, these dollies are constructed to withstand the rigors of industrial use. They often feature additional safety features such as brakes, non-slip surfaces, and padded platforms to prevent damage to the items being transported.

The design of heavy-duty machine dollies can vary, with some models featuring a simple flat platform while others may include sides or enclosures to secure loads. Additionally, many dollies come with swivel wheels, allowing for greater maneuverability in tight spaces, making them invaluable in environments where every inch counts.

Advantages of Heavy-Duty Machine Dollies

1. Enhanced Safety One of the primary benefits of using heavy-duty machine dollies is the increased safety they provide. Lifting heavy items can pose significant risk to workers, including injuries from strains, sprains, or worse. By utilizing a dolly, employees can transport equipment without lifting, thereby minimizing the risk of injury.

2. Increased Efficiency Heavy-duty machine dollies streamline the moving process. Instead of relying on a group of workers to lift and carry heavy machinery, a dolly allows a single person to move items quickly and efficiently. This not only saves time but also boosts productivity by allowing workers to focus on other essential tasks.

heavy duty machine dolly

3. Versatile Applications These dollies are not limited to specific industries. They find applications in manufacturing plants, warehouses, automotive repair shops, and even in home garages. Their versatility means they can be used for various tasks, from moving large machinery and equipment to transporting pallets and heavy boxes.

4. Cost-Effectiveness Investing in heavy-duty machine dollies can be cost-effective in the long run. By reducing the risk of injuries and the associated workers’ compensation claims, businesses can save money. Additionally, improved efficiency can lead to increased output, further enhancing the return on investment.

5. Adaptability to Different Loads Heavy-duty machine dollies can be tailored to meet the specific needs of different loads. Some models come equipped with adjustable platforms or modular designs that can accommodate various sizes and shapes of equipment. This adaptability makes them a convenient choice for diverse applications across industries.

Choosing the Right Heavy-Duty Machine Dolly

When selecting a heavy-duty machine dolly, it is essential to consider the specific requirements of your operations. Key factors include the weight capacity needed, the type of loads being transported, the dimensions of the dolly, and the nature of the flooring in the work environment. Additionally, examining the quality of materials and construction is crucial to ensure durability and longevity.

Furthermore, look for dollies with features that enhance usability, such as ergonomic handles, high-quality wheels for smooth operation, and any additional safety features that might be necessary for your particular application.

Conclusion

Heavy-duty machine dollies are invaluable tools across various industries. Their ability to enhance safety, increase efficiency, and adapt to a range of loads makes them essential for any operation that deals with heavy materials. By investing in high-quality dollies, businesses can improve their logistics, reduce the risk of injury, and ultimately create a safer, more productive work environment. As industries continue to evolve, the importance of such practical tools will remain paramount in the quest for operational excellence.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025