heavy duty rollers for moving equipment

Heavy Duty Rollers for Moving Equipment A Comprehensive Guide

Moving heavy equipment can be a daunting task. Whether in a warehouse, construction site, or industrial setting, the need for efficient and safe equipment transportation is paramount. This is where heavy-duty rollers come into play. These ingenious tools can facilitate the movement of equipment that is cumbersome and difficult to handle manually. In this article, we will explore the various aspects of heavy-duty rollers, including their types, benefits, applications, and best practices for usage.

What are Heavy Duty Rollers?

Heavy duty rollers are specialized devices designed to assist in the movement of heavy loads. They often consist of a set of rollers mounted on a sturdy frame, enabling them to carry and transport equipment with ease. The rollers are typically made from durable materials that can withstand significant weight, making them ideal for heavy machinery, industrial equipment, and large commercial items.

Types of Heavy Duty Rollers

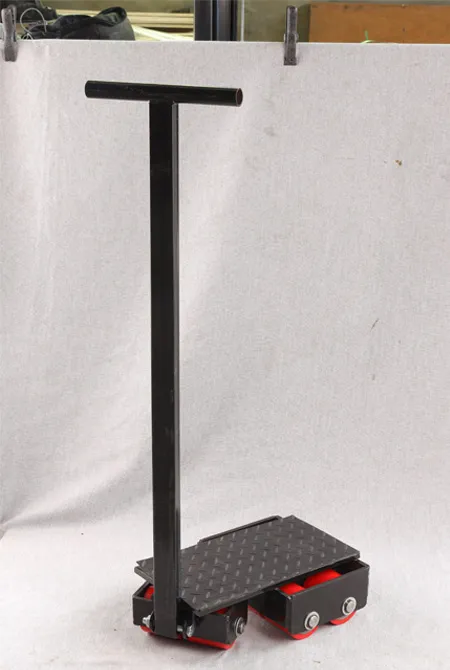

1. Roller Dollies These are flat platforms with rollers underneath, used to glide heavy objects across floors. They come in various sizes and weight capacities, making them suitable for different types of equipment.

2. Skates Similar to dollies, skates are designed specifically for moving heavy machinery. They often have a low profile and can be placed directly under the equipment, allowing for smooth and controlled movements.

3. Turntables These rollers include a rotating platform, enabling users to easily reposition heavy equipment without having to lift it. Turntables are particularly useful in tight spaces where maneuverability is a concern.

4. Power Rollers Equipped with motors, power rollers assist in moving loads automatically. These are ideal for high-volume operations where heavy items need to be moved efficiently and quickly.

Benefits of Using Heavy Duty Rollers

1. Enhanced Safety Moving heavy equipment manually can lead to severe injuries. Heavy duty rollers minimize the risk of accidents by allowing a safer method for transportation.

2. Increased Efficiency With rollers, tasks that might have taken several workers prolonged efforts can now be accomplished more quickly and with fewer personnel. This boosts productivity in a work environment.

3. Cost-Effectiveness While purchasing heavy duty rollers is an upfront investment, they can save money in the long run by reducing labor costs and minimizing the risk of worker injuries.

heavy duty rollers for moving equipment

4. Versatility Heavy duty rollers can be used in various settings, including warehouses, factories, and construction sites, making them a flexible tool for equipment transport.

Applications of Heavy Duty Rollers

Heavy duty rollers have a wide range of applications across different industries. Here are a few notable examples

- Construction Rollers are used to move large machinery and materials like concrete blocks and steel beams. - Manufacturing In factories, heavy equipment needs to be relocated for maintenance or assembly. Rollers facilitate these movements effortlessly. - Warehousing Heavy duty rollers help in transporting bulky inventory items within storage facilities, streamlining the loading and unloading process.

Best Practices for Using Heavy Duty Rollers

To maximize the benefits of heavy duty rollers, consider the following best practices

1. Choose the Right Roller Assess the weight and dimensions of the equipment you need to move to select the appropriate roller type and size.

2. Conduct Regular Maintenance Keep rollers in good working condition by routinely inspecting them for wear and tear.

3. Train Personnel Ensure that your team is well-trained in operating rollers safely and effectively to avoid accidents.

4. Use with Caution Always check the path before moving equipment, ensuring there are no obstacles or hazards that could impede the smooth transfer.

Conclusion

In conclusion, heavy duty rollers are invaluable tools for efficiently moving heavy equipment in various industries. Their ability to enhance safety, improve efficiency, and facilitate cost-saving measures make them essential for any operation dealing with heavy loads. By understanding their types, benefits, applications, and best practices, businesses can optimize their processes and ensure safer working environments. Investing in quality heavy duty rollers is a step towards better operational efficiency and employee safety.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025