heavy equipment moving skates

The Essential Role of Heavy Equipment Moving Skates in Industrial Operations

In the vast realm of industrial operations, the transportation and relocation of heavy machinery and equipment present unique challenges. Heavy equipment moving skates, also known simply as moving skates, have emerged as indispensable tools in this context, enabling smooth and safe relocation of bulky items across various environments. This article delves into the significance of heavy equipment moving skates, their types, functionality, and best practices for effective use.

Understanding Heavy Equipment Moving Skates

Heavy equipment moving skates are specialized platforms designed to facilitate the movement of large and heavy objects. They typically consist of a set of skates fitted with rollers or wheels, allowing equipment to be maneuvered with minimal effort. These skates can handle weights ranging from thousands to millions of pounds, making them essential in industries such as construction, manufacturing, and logistics.

Types of Moving Skates

Moving skates come in various designs to accommodate different needs and specifications

1. Standard Moving Skates These skates are equipped with a basic roller system, suitable for transporting most machinery. They provide a stable base and facilitate lateral movement.

2. Heavy-Duty Skates Engineered for extreme loads, heavy-duty skates are reinforced with robust materials and advanced engineering to handle exceptionally heavy equipment without compromising safety.

3. Air Casters Some moving skates incorporate air caster technology, which utilizes air pressure to lift and glide equipment smoothly. This system significantly reduces friction and allows for easier maneuverability, especially for particularly heavy loads.

4. Adjustable Skates These versatile skates can be customized in terms of width and load capacity, making them suitable for various types of machinery and settings.

Functionality and Benefits

The primary function of heavy equipment moving skates is to ease the burden of relocating heavy machinery

. The benefits of utilizing these tools are numerous- Enhanced Safety Moving heavy equipment manually poses significant risks, including injury. By using moving skates, operators can minimize physical strain and reduce the likelihood of accidents, ensuring a safer workplace.

heavy equipment moving skates

- Increased Efficiency Moving skates streamline the relocation process, allowing for quicker setups and relocations. This efficiency can lead to reduced downtime and less disruption in production schedules.

- Precision Maneuverability The design of moving skates allows for precise movement in tight spaces. This is particularly beneficial in crowded, complex environments where heavy machinery must be navigated around obstacles.

- Cost-Effectiveness Investing in moving skates can lead to significant cost savings. By reducing the risk of damage to equipment and enhancing the efficiency of moves, companies can avoid expenses related to injuries, repairs, and lost productivity.

Best Practices for Use

To maximize the benefits of heavy equipment moving skates, consider the following best practices

1. Assessment of Load Before using moving skates, accurately assess the weight and dimensions of the equipment to ensure you select the appropriate type and number of skates.

2. Surface Preparation Ensure the surface on which the skates will move is clean and even. Any debris or unevenness can impede movement and create safety hazards.

3. Team Coordination When relocating heavy machinery, coordination among team members is crucial. Assign clear roles and communicate throughout the process to enhance safety and efficiency.

4. Regular Maintenance Inspect skates regularly for wear and damage. Maintaining the rollers and overall structure is essential to ensure safe and effective operation.

5. Training Proper training for operators on how to safely and efficiently use moving skates can significantly improve workplace safety and equipment handling.

Conclusion

Heavy equipment moving skates are critical tools for industries that require the transportation of large and heavy machinery. By understanding the various types available and employing best practices for their usage, companies can enhance safety, improve efficiency, and achieve cost-effective solutions in their operations. As industries continue to evolve, the importance of such tools in facilitating the smooth movement of heavy equipment will only grow.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

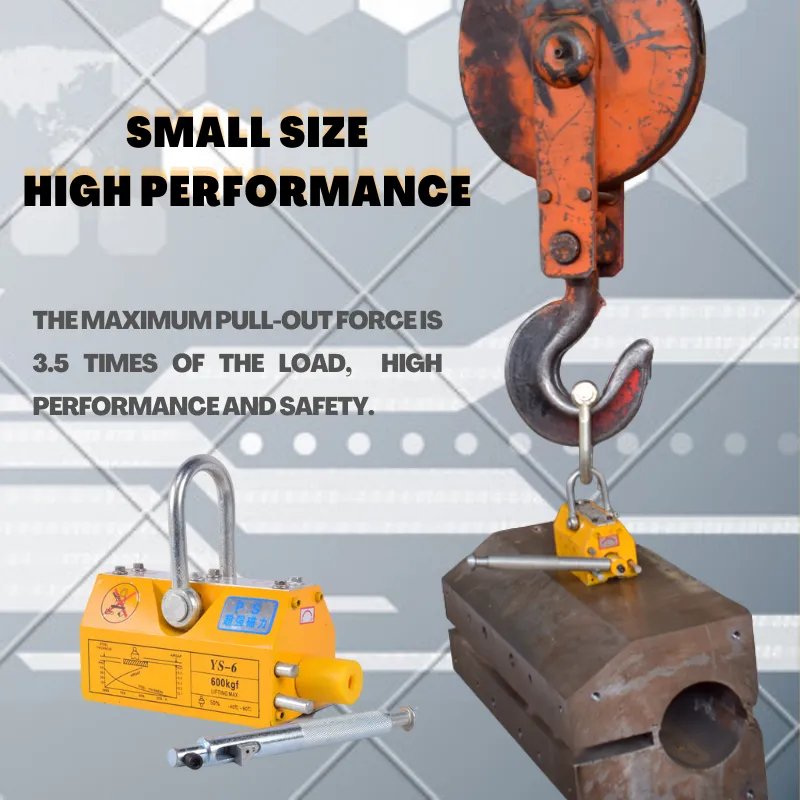

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025