heavy machine dollies

The Importance of Heavy Machine Dollies in Industrial Applications

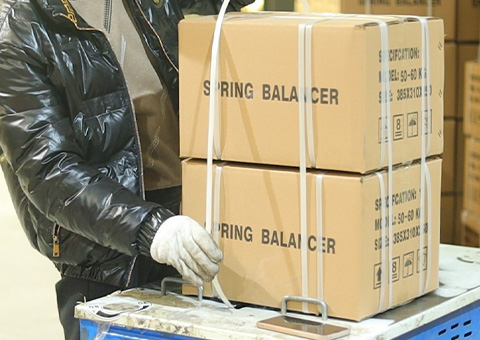

In the realm of industrial equipment handling and logistics, heavy machine dollies play a pivotal role. These specialized tools facilitate the movement of bulky and heavy machinery, which is essential in various sectors including manufacturing, construction, and warehousing. Understanding the significance of heavy machine dollies, their types, and applications can illuminate their indispensable role in enhancing operational efficiency.

Heavy machine dollies are designed to support and transport substantial loads that are typically difficult to move by hand or even with conventional transport equipment. Constructed from robust materials like steel and reinforced plastics, these dollies are engineered to withstand considerable weight without compromising their structural integrity. This design not only ensures durability but also enhances safety during the transportation of heavy equipment.

One of the primary benefits of using heavy machine dollies is the ability they provide to maneuver equipment within confined spaces. In many industrial settings, space is at a premium, and the ability to pivot and move large machines in tight quarters greatly enhances workflow. Whether it is a large generator in a manufacturing plant or a conveyor belt in a warehouse, heavy machine dollies allow for precise positioning, enabling workers to maximize their use of available space.

There are several types of heavy machine dollies, each optimized for specific tasks. For instance, towable dollies enable transport over longer distances and can be connected to vehicles for easy movement. On the other hand, low-profile dollies are ideal for situations where the equipment's height is a concern, allowing for easier loading and unloading. Additionally, adjustable dollies can cater to various load shapes and sizes, providing versatility in industrial operations. Understanding the right type of dolly for specific tasks can significantly reduce the risk of damage to both the machinery and the facility.

heavy machine dollies

Safety is another critical aspect that underscores the necessity of heavy machine dollies. The movement of heavy machinery inherently involves risks, including potential injuries to workers or damage to goods and infrastructure. By utilizing dollies, workers are able to minimize manual lifting and reduce the likelihood of accidents resulting from improper handling techniques. Furthermore, many modern dollies come equipped with safety features, such as brakes, locking mechanisms, and cushioned surfaces, which help stabilize loads during transit.

The efficiency gained from using heavy machine dollies also has a direct impact on operational costs. By streamlining the process of moving heavy equipment, companies can significantly decrease the time spent on logistics. This time-saving translates to increased productivity, allowing businesses to allocate resources more effectively. In industries where downtime can lead to substantial financial losses, investing in reliable and efficient machine dollies is not just an expense; it is a strategic move towards sustaining competitiveness.

In addition to heavy machine dollies, it is crucial to recognize the role of training in the safe use of these tools. Workers should be adequately trained not only in the operation of dollies but also in understanding load capacities and the proper techniques for securing equipment. Training empowers employees to utilize machinery safely and effectively, reducing the risk of accidents and injuries.

In conclusion, heavy machine dollies are an essential component in the landscape of industrial operations, pivotal for the safe and efficient movement of heavy equipment. With a variety of types designed for different tasks, they provide the necessary support for workers to maneuver significant loads safely and effortlessly. The advantages they offer in terms of safety, efficiency, and cost-effectiveness cannot be overstated. As industries continue to evolve and innovate, the role of heavy machine dollies will remain critical, aiding businesses in meeting their logistical challenges while enhancing productivity and workplace safety. Proper training and maintenance further ensure that these vital tools can continue to serve their purpose effectively, embodying the intersection of safety, efficiency, and reliability in industrial applications.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025