Heavy Equipment Moving Solutions for Efficient Machinery Relocation and Setup

Heavy Machinery Relocation An Overview

Heavy machinery relocation is a critical process in various industries, including construction, manufacturing, and mining. Due to their size, weight, and complexity, heavy machines require careful planning and execution when being moved from one location to another. This article delves into the intricacies of heavy machinery relocation, emphasizing its significance, challenges, and best practices.

The Importance of Heavy Machinery Relocation

Heavy machinery, such as excavators, cranes, bulldozers, and generators, plays a crucial role in large projects. When a project site changes, or when equipment needs to be brought to a new location for a different phase of work, relocating heavy machinery is essential. Effective relocation can ensure minimal downtime, reduce operational costs, and enhance project efficiency. Failure to properly relocate machinery may lead to delays in project timelines, increased labor costs, and even potential safety hazards.

Planning the Relocation Process

The first step in successful heavy machinery relocation is meticulous planning. This involves several key considerations

1. Assessment of Equipment Different machines have unique requirements in terms of transportation. Assessing the type of machinery, weight, dimensions, and any special handling needs is vital. Understanding the specific characteristics of each piece of equipment will inform the selection of transportation methods and routes.

2. Transportation Logistics Choosing the right mode of transportation is crucial. Options include flatbed trucks, lowboy trailers, or specialized equipment like hydraulic trailers. The weight and dimensions of the machinery will dictate which vehicle is appropriate. Furthermore, logistics concerning permits, route planning, and timing must be addressed. Some routes may require permits due to weight limits, while others might need scheduling to avoid peak traffic hours.

3. Safety Measures Safety is paramount in heavy machinery relocation. This includes ensuring that all equipment is properly secured during transport to prevent movement that could lead to damage or accidents. Additionally, personnel involved in the relocation should be trained and equipped with personal protective equipment (PPE) to handle machinery safely during loading, transportation, and unloading.

4. Communication Engaging all stakeholders, from machine operators to transportation teams, is essential. Clear communication can prevent misunderstandings and ensure everyone involved is aware of their responsibilities throughout the relocation process.

Challenges Faced in Heavy Machinery Relocation

heavy machinery relocation

Despite careful planning, heavy machinery relocation can present various challenges

1. Logistical Issues Unexpected hurdles such as road closures or weight restrictions can arise, requiring quick adaptations to the plan. These issues can lead to delays and additional costs if not managed efficiently.

2. Weather Conditions Adverse weather conditions can impact transportation safety and equipment handling. Rain, snow, or ice can lead to slippery surfaces and reduced visibility, necessitating a review of transportation schedules and safety protocols.

3. Technical Difficulties Heavy machinery may sometimes require disassembly before transportation to fit onto transport vehicles. This can add complexity and time to the relocation process, necessitating skilled personnel for safe and effective handling.

Best Practices for Successful Relocation

To mitigate challenges and enhance the efficiency of heavy machinery relocation, consider the following best practices

- Comprehensive Training Ensure that all personnel involved in the relocation process are adequately trained. This includes knowledge of safety protocols, equipment handling, and emergency procedures.

- Regular Maintenance Keep machinery in optimal condition to avoid unforeseen issues during relocation. Regular checks can identify potential concerns before they arise.

- Utilize Technology Employing technology such as GPS tracking, project management software, and 3D modeling can enhance logistics planning and execution.

Conclusion

Heavy machinery relocation is a complex yet essential aspect of numerous industries. By understanding its significance, anticipating challenges, and adhering to best practices, companies can ensure that the relocation process is efficient, safe, and cost-effective. With careful planning and execution, businesses can minimize disruptions and keep projects on track, ultimately contributing to successful outcomes in their operational endeavors.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

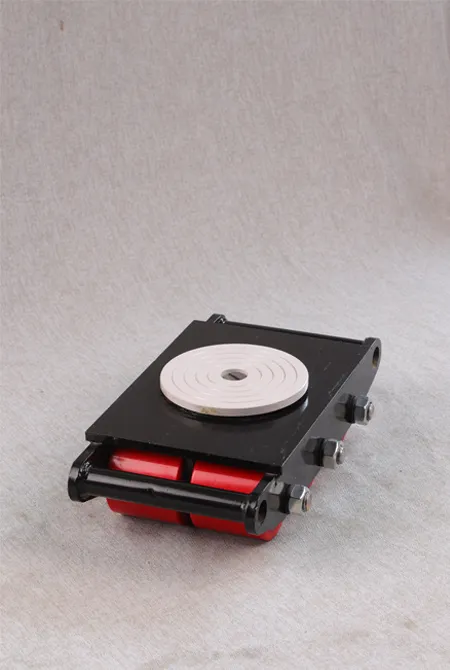

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025