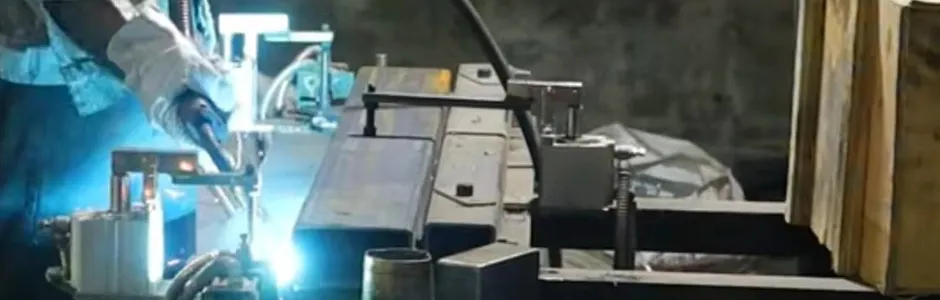

i beam for gantry crane

The Role of I-Beams in Gantry Crane Construction

Gantry cranes play a vital role in numerous industrial applications, including manufacturing, warehouse operations, and construction sites. These versatile cranes allow for the movement of large, heavy materials with ease. A crucial component that contributes to the functionality and stability of gantry cranes is the I-beam, an essential structural element that supports various heavy loads.

What is an I-Beam?

An I-beam, also known as an H-beam or Universal Beam, is a structural steel component characterized by its I-shaped cross-section. The horizontal components of the I are known as flanges, and the vertical component is called the web. This design is instrumental in providing strength and rigidity while minimizing weight, making it ideal for use in gantry cranes. The flanges effectively resist bending, while the web handles shear forces, providing an optimal balance of structural integrity and material efficiency.

Importance of I-Beams in Gantry Cranes

1. Load Distribution One of the primary reasons for incorporating I-beams in gantry cranes is their ability to distribute loads evenly. When a crane lifts heavy materials, the forces exerted on the structure can be significant. The I-beam's design helps in dissipating these forces along its length, preventing localized stresses that could lead to structural failure.

i beam for gantry crane

2. Stability and Rigidity I-beams provide the necessary rigidity to maintain the crane's shape and stability when in operation. This stability is crucial for safety, ensuring that the crane does not sway or tip over while lifting loads. In settings where precision is necessary, such as during the assembly of large components, the rigidity afforded by I-beams ensures accurate positioning.

3. Versatility in Design The flexibility of I-beams allows engineers to design gantry cranes for various applications and environments. The size and material of the I-beams can be tailored to meet specific load requirements, making them suitable for different industries ranging from shipping to heavy machinery manufacturing. This versatility makes I-beams an ideal choice for custom-built gantry cranes.

4. Ease of Installation I-beams are relatively lightweight compared to other structural components with similar strength capabilities. This feature enables easier handling and installation, reducing the time and labor involved in erecting a gantry crane. The ability to use lighter materials without sacrificing strength also contributes to cost-efficiency in crane construction.

5. Durability and Longevity Made primarily from steel, I-beams are resistant to environmental degradation and can withstand harsh operating conditions. This durability translates to a longer lifespan for gantry cranes, making them a worthwhile investment for businesses that rely on heavy lifting equipment.

Conclusion

In conclusion, I-beams are fundamental components in the construction of gantry cranes, providing essential benefits such as load distribution, stability, and design versatility. Their ability to withstand heavy loads while maintaining structural integrity makes them indispensable in modern industrial applications. As industries continue to evolve and demand more efficient lifting solutions, the importance of I-beams in gantry crane design and deployment will only grow. By understanding the key role of I-beams in this context, engineers and operators can ensure the reliable and safe operation of gantry cranes in various settings, ultimately contributing to enhanced productivity and safety in the workplace.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025