i beam for gantry crane

The Role of I-Beams in Gantry Crane Design

Gantry cranes are essential pieces of equipment in various industries, facilitating the movement of heavy loads with ease and precision. Among the critical components that make these cranes effective are the I-beams (also known as H-beams) that form the structural backbone of the crane. This article explores the significance of I-beams in gantry crane design, their advantages, and considerations for their selection.

Understanding I-Beams

I-beams derive their name from their distinctive shape, resembling the letter I. This profile is engineered to handle bending and shear forces more effectively than other forms of beams, making them an excellent choice for heavy-duty applications. Typically made from steel or aluminum, I-beams possess high strength-to-weight ratios which are crucial for the intensive lifting operations of gantry cranes.

Structural Integrity

In a gantry crane, the I-beam serves multiple functions. It acts as the horizontal support structure that carries the load being lifted. The design of the I-beam allows it to resist bending moments that occur during the lifting process. This structural integrity is essential to prevent deformation and failure, ensuring not only the safety of the operations but also the longevity of the crane itself.

Additionally, the I-beam’s web (the vertical section) provides resistance against shear forces, while the flanges (the horizontal sections) take on the bending moments. This dual-functionality allows for a lighter frame without compromising strength, which can contribute to overall cost efficiency in crane operations.

Versatility and Efficiency

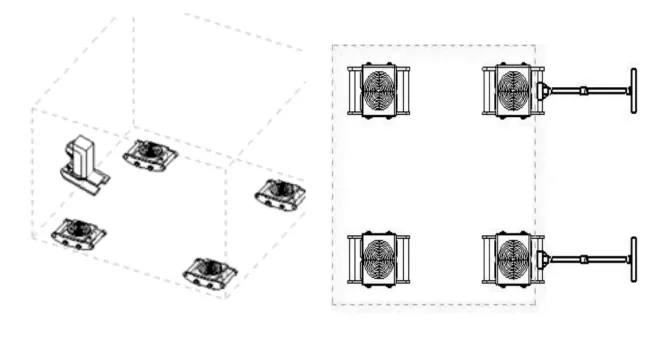

i beam for gantry crane

One of the most significant advantages of using I-beams in gantry cranes is their versatility. I-beams can be manufactured in various sizes and strengths, making it possible to customize gantry cranes to meet specific operational requirements. This adaptability means that whether in a construction site, warehouse, or manufacturing plant, the appropriate I-beam can be selected to optimize performance.

Furthermore, the precise engineering of I-beams also leads to improved energy efficiency. As they require less material than other beam types for the same strength, they help reduce the dead weight of the crane. Lighter cranes consume less energy during operation, thereby lowering operational costs and enhancing overall productivity.

Selection Considerations

When choosing I-beams for a gantry crane, several factors must be taken into account. The load capacity, span length, and environmental conditions (such as exposure to corrosive materials) are vital considerations. Engineers must also evaluate the frequency of use and the types of loads to be lifted. By carefully considering these factors, engineers can select I-beams that ensure optimal safety and performance.

Additionally, structural analysis must be conducted to determine the appropriate size and type of I-beam to withstand dynamic loads, especially in environments where crane operation could lead to additional stresses.

Conclusion

I-beams play a pivotal role in the design and functionality of gantry cranes. Their strength, versatility, and efficiency make them indispensable in lifting applications across various industries. As technology advances and engineering practices evolve, the integration of innovative materials and designs will further enhance the performance of I-beams in gantry crane systems. Ultimately, selecting the right I-beam is crucial for achieving safety, durability, and efficiency in crane operations, contributing to the smooth running of industrial processes worldwide.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025