industrial gantry

The Industrial Gantry A Modern Key to Efficiency and Precision

In the world of industrial manufacturing and logistics, efficiency and precision are paramount. One of the most instrumental tools that facilitate these objectives is the industrial gantry. This versatile and robust structure has transformed how goods are moved, assembled, and processed in various sectors, including construction, automotive, aerospace, and warehousing. By providing a reliable method of transporting heavy loads with precision, industrial gantries have become indispensable in contemporary industrial environments.

Understanding the Industrial Gantry

An industrial gantry is essentially a framework that consists of a system of beams supported by legs, allowing for the movement of equipment or goods across an area

. Unlike traditional cranes, which are often fixed in one location, gantry systems can be configured to move along tracks, granting them substantial flexibility. This adaptability enables companies to optimize their workflows, minimize manual handling, and enhance safety in the workplace.Gantry systems can be classified into several categories, including mobile gantries, fixed gantries, and gantries with integrated cranes. Mobile gantries can be easily repositioned within a facility, making them ideal for tasks that require frequent relocation. Fixed gantries, on the other hand, are permanently installed and best used in environments where a steady, repeated operation is expected. Each type caters to specific needs, ensuring that industries can choose the best solution for their operational requirements.

Advantages of Industrial Gantries

One of the primary advantages of industrial gantries is their ability to handle heavy loads with ease. Most gantry systems are constructed from materials like steel or aluminum, which provide the necessary strength and durability while keeping the structure relatively lightweight. This capability allows for the safe movement of components weighing thousands of pounds, reducing the risk of workplace injuries associated with manual lifting.

industrial gantry

Moreover, gantry systems enhance productivity. The incorporation of powered movement options, including electric chain hoists and motorized tracks, allows for seamless transport of materials from one point to another. This mechanization significantly reduces downtime and streamlines assembly processes, contributing to shorter production cycles and increased output.

Precision in Manufacturing

In addition to their robustness, industrial gantries excel in precision operations. The ability to position loads exactly where needed is crucial in fields such as aerospace and automotive manufacturing, where even the slightest misalignment can result in significant quality control issues or costly rework. Advanced gantry systems often incorporate automated controls and sensors, enabling them to carry out intricate tasks with a high level of accuracy.

Furthermore, the use of gantries in assembly lines can lead to improved ergonomics. By strategically positioning tools and materials at a comfortable height and reach, workers can perform their tasks more efficiently, reducing fatigue and the risk of repetitive strain injuries.

Conclusion

As industries continue to evolve and face new challenges, the demand for efficient, safe, and precise tools has never been greater. The industrial gantry stands out as a beacon of innovation in this landscape, offering a flexible solution that meets the needs of modern manufacturing and logistics operations. With ongoing advancements in technology, the future of industrial gantries looks promising—setting the stage for even greater efficiency and precision in the industrial sector. As businesses invest in these systems, they not only enhance their productivity but also contribute to safer work environments, ultimately driving growth and success in an increasingly competitive market.

-

Portable 2000 lb Gantry Crane | Heavy-Duty & AdjustableNewsAug.30,2025

-

Versatile Lifting Solutions with Gantry and Overhead CranesNewsAug.29,2025

-

The Versatile Mobile Gantry Crane SolutionNewsAug.29,2025

-

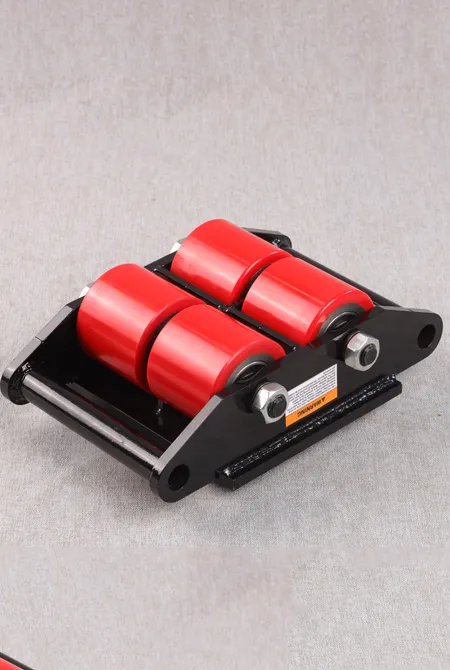

Reliable Movement with Heavy Machinery Skates and RollersNewsAug.29,2025

-

Reliable Lifting Performance with 2000 lb Gantry Crane and 2 Ton Overhead SystemsNewsAug.29,2025

-

Maximize Lifting Efficiency with PML Magnetic LiftersNewsAug.29,2025

-

Efficient Relocation Starts with Reliable Machinery MoversNewsAug.29,2025