industrial gantry

The Rise of Industrial Gantries Transforming Manufacturing Processes

In the realm of modern manufacturing, efficiency and precision are paramount. As industries evolve and the demand for higher productivity increases, one technological advancement stands out the industrial gantry. These robust frameworks are essential in various operations, from construction to assembly. This article delves into the significance of industrial gantries, their applications, and the technological innovations driving their evolution.

Understanding Industrial Gantries

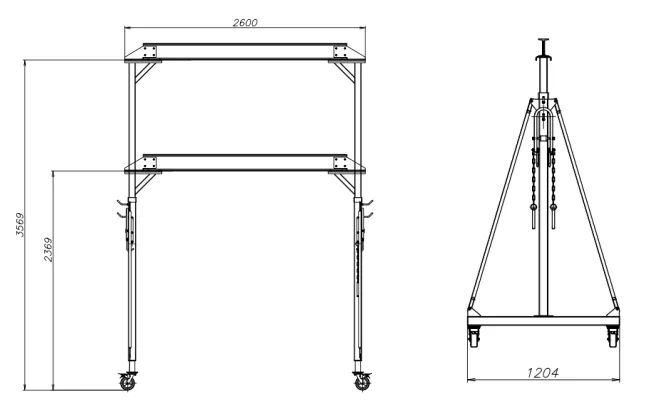

An industrial gantry is a type of structure that spans across an area to support equipment such as cranes, hoists, and machinery

. Typically built from steel or aluminum, they provide a stable and movable platform that can traverse large distances, making them indispensable for various manufacturing and construction tasks. The design of gantries can vary widely depending on their intended use, load requirements, and working environment.Applications Across Industries

1. Manufacturing In manufacturing environments, gantries play a critical role in assembling products. They often integrate automated systems for loading and unloading materials. By utilizing gantries, manufacturers can streamline processes and improve overall workflow. For instance, in automotive plants, gantries are used for moving heavy components like engines and car bodies, ensuring safety and efficiency.

2. Construction In construction settings, gantries facilitate the movement of heavy materials. They are frequently used on construction sites to lift beams, bricks, and other supplies to significant heights. This application not only increases productivity but also enhances safety, as workers can maneuver heavy loads without human intervention.

3. Logistics and Warehousing The logistics industry also benefits significantly from gantry systems. They aid in the automated transport of goods within warehouses and distribution centers. With the rise of e-commerce and the need for rapid order fulfillment, gantry systems are essential for managing inventory more effectively and speeding up the shipping process.

industrial gantry

4. Maritime Operations Gantries are pivotal in shipyards and ports. They are utilized for loading and unloading containers from vessels, ensuring that operations adhere to tight schedules. This application significantly contributes to the efficiency of global trade and supply chains.

Innovations in Gantry Technology

As technology progresses, industrial gantries have undergone remarkable advancements. The integration of robotics and automation is perhaps the most significant shift. Modern gantry systems can utilize robotic arms for precision tasks, which reduces human error and increases production speed. This shift towards automation is crucial in addressing labor shortages and enhancing productivity in the face of increasing demands.

Moreover, the advent of smart technology has enabled the implementation of IoT (Internet of Things) capabilities within gantries. This allows for real-time monitoring and data analysis, which can lead to enhanced decision-making processes. For example, sensors can track the performance and health of gantry systems, providing alerts for maintenance needs and reducing downtime.

The use of lightweight materials, such as advanced composites, is another area of innovation. These materials can significantly reduce the weight of gantries, allowing for easier transport and installation while maintaining structural integrity and load-bearing capacity.

Conclusion

Industrial gantries are pivotal to the advancement of manufacturing and construction industries. Their versatility offers diverse applications that enhance safety, efficiency, and precision in various operations. With continuous innovations in technology, including automation and smart capabilities, gantries will undoubtedly play an even more crucial role in shaping the future of industries. As we move towards an increasingly automated world, the importance of investing in advanced gantry systems cannot be overstated, marking a transformative era in industrial operations. As businesses seek to optimize their processes and meet the demands of the modern marketplace, the integration of industrial gantries into their operations will be key to achieving those goals.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025