Industrial Lifting Magnets for Efficient Heavy Load Handling and Secure Transport Solutions

Industrial Lifting Magnets Revolutionizing Material Handling

In the fast-paced world of industrial operations, efficiency and safety are paramount. One of the key technologies driving improvements in material handling is the use of industrial lifting magnets. These powerful devices facilitate the movement of ferromagnetic materials, allowing for seamless transportation across factory floors, warehouses, and construction sites. This article delves into the significance of industrial lifting magnets, their types, advantages, and applications.

At the core of industrial lifting magnets is their ability to generate a magnetic field strong enough to lift heavy loads, such as steel plates, rods, and other ferrous components

. These magnets come in various forms, including permanent magnets, electro magnets, and battery-operated magnets. Each type offers distinct benefits tailored to specific industrial needs.1. Permanent Lifting Magnets These magnets utilize permanent magnet technology to provide a consistent lifting force without requiring an external power source. They are known for their reliability and durability, making them a popular choice for routine lifting tasks. Permanent magnets are especially effective for handling smaller materials or in applications where power availability may be a concern.

2. Electromagnets Unlike permanent magnets, electromagnets use electrical current to create a magnetic field. These lifting devices offer adjustable lifting capacities and can easily be turned on or off, providing flexibility for various applications. This feature is particularly beneficial in dynamic work environments where loads may vary. Electromagnets are often used in heavy-duty applications such as scrap metal yards and steel mills.

industrial lifting magnets

3. Battery-Operated Magnets A hybrid between permanent and electromagnets, battery-operated magnets provide flexibility without the need for continuous power supply. They are particularly useful in situations where mobility is crucial, such as on construction sites, enabling workers to move materials efficiently without being tethered to power sources.

The advantages of employing industrial lifting magnets are manifold. First and foremost, they enhance safety by minimizing the risk of manual handling injuries. Heavy lifting can lead to accidents, but with magnets, operators can effortlessly lift and transport loads without physical strain. Additionally, these magnets help to streamline operations, increase productivity, and reduce the time spent handling materials.

Moreover, lifting magnets can be integrated into existing material handling systems, including cranes and conveyor belts, leading to significant improvements in workflow. The versatility of these devices allows them to be employed in various sectors such as manufacturing, construction, automotive, and recycling.

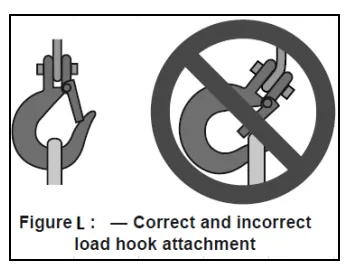

While lifting magnets offer numerous benefits, it is essential to ensure proper usage and maintenance. Regular inspection and adherence to weight limits are vital to prevent accidents and equipment failure. Training operators in the safe and effective use of these tools further enhances the safety and efficiency of operations.

In conclusion, industrial lifting magnets are a transformative technology in material handling. Their ability to lift heavy ferrous loads efficiently and safely not only improves operational workflows but also contributes to workplace safety. With advancements in magnet technology, industries can expect continued innovations that will further enhance the capabilities and applications of lifting magnets in the years to come. As industries evolve, embracing these tools will be key to maintaining competitiveness and advancing operational excellence.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025