Innovative Applications of Mobile Gantry Systems in Modern Transportation and Infrastructure Solutions

The Marvels of the Travelling Gantry

In the ever-evolving landscape of industrial machinery, the travelling gantry crane stands as a remarkable feat of engineering, embodying strength, versatility, and efficiency. From shipyards to construction sites, these cranes are indispensable tools that enhance productivity and safety in heavy lifting operations.

Understanding the Travelling Gantry

A travelling gantry crane is defined by its robust frame supported by two legs that move on rails. This design allows for the crane to traverse along a predetermined route, providing significant operational flexibility. The gantry consists of a horizontal beam, known as the gantry girder, from which a hoisting mechanism is suspended. The crane's ability to travel horizontally allows it to cover large areas and perform tasks that would be cumbersome or impossible for stationary cranes.

Applications Across Industries

The versatility of travelling gantry cranes makes them suitable for a broad range of applications. In shipbuilding, these cranes facilitate the construction and repair of vessels by transporting heavy components from one construction stage to another. Their reach and strength are crucial when maneuvering large steel plates or entire hull sections.

In the construction sector, travelling gantries are employed on large construction sites, particularly when erecting tall structures. They can lift heavy steel beams and transport materials across the site, streamlining the building process. This efficiency reduces labor costs and minimizes the time required to complete projects.

Moreover, in the manufacturing realm, travelling gantries are commonly used in factories for material handling. They provide quick access to heavy loads and contribute to a more organized workflow. Their ability to move from one point to another significantly enhances productivity, enabling factories to operate smoothly and effectively.

travelling gantry

Safety Features and Innovations

Safety is paramount in industrial settings, and travelling gantry cranes are built with numerous safety features. Modern versions come equipped with advanced control systems that reduce the risk of operator error. These cranes are often fitted with sensors and alarms that monitor load weights, preventing overload conditions that can lead to catastrophic failures.

In recent years, the advent of automation and smart technology has transformed the operation of travelling gantry cranes. Remote control systems allow operators to manage the cranes from a safe distance, reducing the risk of accidents. Incorporating artificial intelligence and machine learning algorithms, these cranes can optimize load distribution and navigation, further enhancing safety and efficiency.

Environmental Considerations

As industries strive to adopt more sustainable practices, travelling gantry cranes are increasingly designed with energy efficiency in mind. Electric-powered gantries, for instance, produce fewer emissions compared to their diesel-powered counterparts. Additionally, advancements in materials used for construction have led to lighter yet stronger gantries, reducing energy consumption while maintaining their lifting capabilities.

Conclusion

The travelling gantry crane exemplifies the intersection of innovation and functionality in modern engineering. Its robust design, versatility, and safety features make it an essential asset across multiple industries. As technology continues to advance, we can expect even greater improvements in the efficiency and safety of these cranes, solidifying their role in the future of heavy lifting and construction operations. Embracing these innovations will ensure that the travelling gantry remains a pillar of industrial productivity for years to come.

-

Dawei Hand Pallet Truck 1200mm, 2000–5000 KGS Heavy-DutyNewsNov.17,2025

-

Dawei Hand Pallet Truck, Fork Length 1200mm, 2000–5000kgNewsNov.17,2025

-

Large Equipment Movers – Safe, Insured & On-Time ServiceNewsNov.17,2025

-

Machine Moving Dollies | Heavy-Duty, Low-Profile, SafeNewsNov.17,2025

-

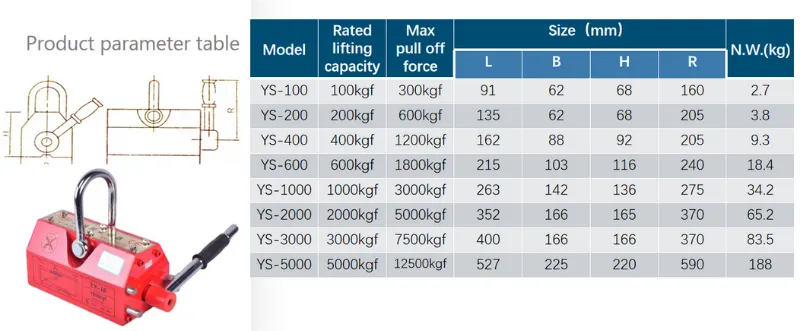

Permanent Lifting Magnet - Heavy-Duty, Safe, Quick ReleaseNewsNov.11,2025

-

PML 1000 Lifting Magnet - Heavy-Duty, Safe, No PowerNewsNov.11,2025

-

Large Equipment Movers: Safe, Fast, Certified ProsNewsNov.11,2025