Innovative Hoisting Solutions for Efficient Gantry Systems in Heavy Lifting Applications

Hoist Gantry System An Overview

The hoist gantry system is a crucial piece of equipment used in various industrial applications, particularly in manufacturing, construction, and logistics. This system combines the functionalities of a hoist and a gantry crane, allowing for the safe and efficient lifting and moving of heavy loads within a defined work area. With the increasing demands for productivity and safety in workplaces, the hoist gantry system has emerged as an essential tool for many industries.

Design and Components

A hoist gantry system typically consists of several key components. The main structure is the gantry, which is a framework supported by vertical legs and horizontal beams. This framework is often constructed from steel or aluminum, providing the necessary strength and stability to support heavy weights. At the top of the gantry is the hoist, a device that uses a mechanism (usually electric or manual) to lift and lower loads.

The movement of the hoist is usually facilitated by a trolley that travels along the horizontal beam of the gantry. This design allows for lateral movement, enabling the operator to position the load accurately. Additionally, many hoist gantry systems come equipped with various safety features, including limit switches, emergency stops, and overload protection, ensuring safe operation.

Applications

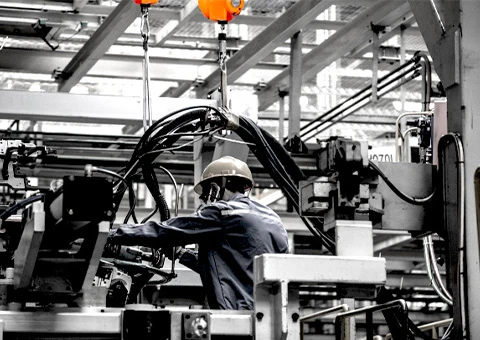

Hoist gantry systems are utilized across diverse industries. In manufacturing, they are often used to move components and assemblies efficiently along production lines. The automotive, aerospace, and heavy machinery industries particularly benefit from this equipment due to the heavy components involved.

In construction, hoist gantry systems facilitate the movement of building materials and equipment, contributing to more efficient project workflows. They are also commonly found in warehouses and distribution centers, where they help in the loading and unloading of goods, thereby streamlining the supply chain process.

hoist gantry system

Benefits

One of the primary advantages of hoist gantry systems is their versatility. These systems can be easily customized to meet specific application needs. Furthermore, they can be made portable, allowing for use in different locations without permanent installation, which is crucial for project-based work.

Another key benefit is the efficiency they bring to lifting operations. By enabling fast and safe movement of heavy loads, they reduce manual handling risks and enhance productivity. The ergonomic design of many hoist gantry systems also helps in minimizing worker fatigue and injuries associated with lifting heavy items.

Considerations

When selecting a hoist gantry system, it is essential to consider several factors. The weight capacity is critical, as it needs to support the heaviest load expected in the specific application. Additionally, the height of the gantry and the span between the legs must be adequate to maneuver loads within the workspace. Other considerations include the operating environment, potential need for portability, and maintenance requirements.

Conclusion

In conclusion, the hoist gantry system plays an integral role in modern industrial operations. By combining the lifting capabilities of a hoist with the stability of a gantry structure, these systems enhance safety and efficiency in moving heavy loads. As industries continue to evolve and demand more productivity, the importance of hoist gantry systems is set to grow, making them an indispensable asset in various sectors. Whether in manufacturing, construction, or warehousing, understanding the benefits and applications of hoist gantry systems is essential for businesses looking to optimize their operations and enhance safety protocols.

-

the-power-of-trolley-cargo-and-machinery-moving-solutionsNewsAug.22,2025

-

exploring-magnetic-lifting-devices-for-efficient-steel-plate-handlingNewsAug.22,2025

-

the-essential-guide-toportal-craneNewsAug.22,2025

-

enhancing-efficiency-in-permanent-magnetic-liftersNewsAug.22,2025

-

heavy-duty-machinery-movers-and-material-handling-solutionsNewsAug.22,2025

-

the-comprehensive-guide-to-adjustable-gantry-cranesNewsAug.22,2025

-

The Ultimate Guide to Heavy Machinery Moving EquipmentNewsAug.04,2025