Innovative Magnetic Lifter Solutions for Efficient Handling and Transport of Heavy Loads in Industrial Applications

The Importance and Functionality of Magnetic Lifters

Magnetic lifters are innovative tools designed to lift heavy ferromagnetic materials with ease. They utilize the principles of magnetism, making them an essential piece of equipment in various industries, including manufacturing, construction, and logistics. Their ability to improve efficiency and safety in material handling has led to their growing popularity.

How Magnetic Lifters Work

The basic principle behind magnetic lifters lies in their use of permanent magnets or electromagnets. Permanent magnetic lifters use powerful magnets that create a magnetic field, allowing them to cling onto ferromagnetic materials like iron and steel. Electromagnetic lifters, on the other hand, become magnetized when electric current flows through a coil, allowing them to lift loads upon activation and release them once the current is switched off.

The design of magnetic lifters usually consists of a robust, compact body with a handle for easy maneuvering. Depending on the model, these lifters can support varying weights, from a few hundred kilograms to several tons. This versatility makes them suitable for different applications, ensuring a significant reduction in manual labor and the associated risks.

Benefits of Using Magnetic Lifters

1. Increased Efficiency Magnetic lifters streamline the transportation of heavy materials. Operators can quickly pick up and move items without the need for additional equipment such as cranes or hoists, significantly reducing the time needed for material handling.

2. Safety By minimizing human intervention in the lifting process, magnetic lifters enhance workplace safety. Workers are less exposed to the dangers of heavy lifting, thereby reducing the likelihood of injuries and accidents.

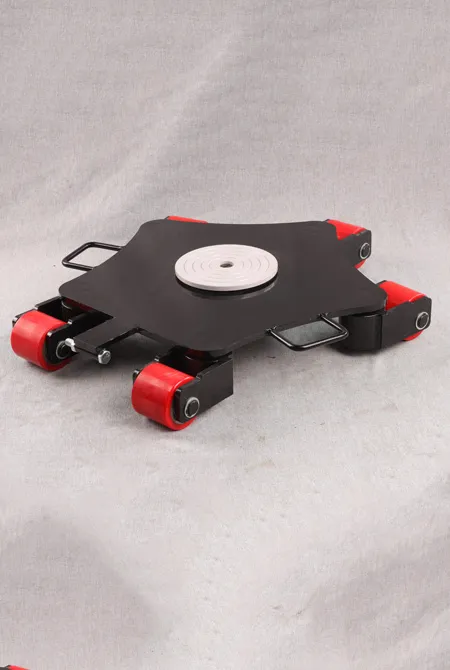

magnetic lifter

3. Cost-Effective The use of magnetic lifters can lead to lower labor costs and decreased equipment wear and tear. Since they require minimal maintenance and have a long lifespan, businesses can save money in the long run.

4. Versatility These lifters can be used in various environments, from factories to warehouses and construction sites. Their adaptability means they can handle different shapes and sizes of materials, making them an invaluable tool for many operations.

5. Reduced Risk of Damage Unlike traditional lifting methods, which may entail straps or hooks that can damage the surface of materials, magnetic lifters provide a secure grip without causing scratches or dents, preserving the integrity of the materials being handled.

Applications of Magnetic Lifters

Magnetic lifters find numerous applications across various sectors. In the manufacturing industry, they are used to move sheet metal, plates, and other heavy components with precision. In construction sites, these devices aid in lifting steel beams and large equipment. In metal processing industries, magnetic lifters facilitate the handling of finished products or raw materials, thus enhancing overall productivity.

Additionally, the automotive sector employs magnetic lifters for transporting parts during assembly lines, while warehouses utilize them to manage high volumes of inventory efficiently. Their lightweight design coupled with robust lifting capabilities translates to significant operational advantages.

Conclusion

Magnetic lifters are a testament to the advancements in material handling technology. By harnessing the power of magnetism, they offer a safe, efficient, and cost-effective solution for lifting heavy materials. As industries continue to evolve and prioritize efficiency and safety, the importance of magnetic lifters in streamlining operations cannot be overstated. Investing in such innovative tools not only enhances productivity but also fosters a safer work environment, ultimately leading to better outcomes for businesses and their employees.

-

The Ultimate Guide to Heavy Machinery Moving EquipmentNewsAug.04,2025

-

The Evolution of Large Equipment MoversNewsAug.04,2025

-

Maximizing Efficiency with PML Magnetic Lifters in Industrial OperationsNewsAug.04,2025

-

Choosing the Best Small Gantry CraneNewsAug.04,2025

-

Innovations in Permanent Lifting Magnet TechnologyNewsAug.04,2025

-

How to Maintain Your Adjustable Gantry Crane for LongevityNewsAug.04,2025

-

PML 6 Lifting Magnet Troubleshooting GuideNewsJul.25,2025