Innovative Solutions for Efficiently Transporting Heavy Equipment Using Roller Systems and Technology

The Importance of Rollers in Moving Heavy Equipment

In various industries, the transportation of heavy equipment is a fundamental aspect of operations. Whether it is in construction, mining, or manufacturing, the ability to move hefty machinery safely and efficiently is crucial. One of the most effective tools for facilitating this process is the roller. Rollers, specifically designed for moving heavy equipment, have revolutionized how we transport large objects, contributing significantly to efficiency and safety.

The Importance of Rollers in Moving Heavy Equipment

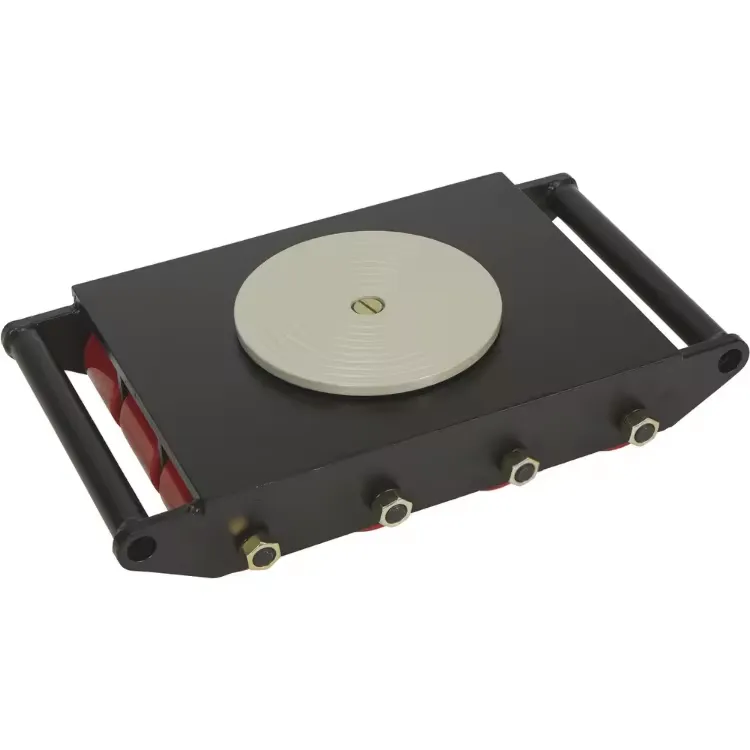

One prominent type of roller system is the use of heavy-duty spherical rollers or cylindrical rollers. These systems are often used in conjunction with dollies which provide stability and control. The capacity of these rollers varies—some can support loads exceeding several tons, making them ideal for the heaviest of machinery. The strength and design of the rollers ensure that they can withstand the stresses of moving heavy equipment, reducing wear and tear on both the machine and the surface it travels over.

rollers moving heavy equipment

Moreover, the use of rollers can enhance precision in placement. In many construction scenarios, heavy machinery needs to be positioned with precision, sometimes in confined spaces. Rollers allow for finer control in these situations. Operators can make minute adjustments to the position of the equipment without the inherent risk of damaging the machinery or the site. This ability to maneuver equipment in a controlled manner is invaluable in environments where space is limited.

Safety is another critical factor in the use of rollers for moving heavy equipment. Transporting heavy machinery often presents risks—not only to the equipment itself but also to workers in the vicinity. By using rollers, the likelihood of accidents diminishes significantly. The reduced need for lifting or manual manipulation of heavy loads lowers the chance of musculoskeletal injuries among workers. Furthermore, modern roller systems often include safety features such as locks to prevent movement during loading and unloading, ensuring that both the equipment and the operators are protected.

The application of rollers in various industries illustrates their versatility. In construction, they are essential in moving bulldozers and backhoes. In manufacturing settings, rollers facilitate the transport of heavy press machines and assembly tools. The mining industry also heavily relies on rollers for the movement of excavators and drilling equipment. The ability to adapt roller systems to different equipment types is a testament to their design and functionality.

In conclusion, rollers are an indispensable tool in the movement of heavy equipment. Their design not only helps to carry immense loads with minimal effort, but they also enhance safety, precision, and efficiency in operations. As industries continue to evolve and demand for heavy machinery increases, the significance of rollers in these processes will undoubtedly grow. The integration of advanced materials and technology will likely lead to even more innovative roller systems, further enhancing their role in heavy equipment transportation. The future of moving heavy equipment looks promising, with rollers at the forefront of these developments.

-

The Ultimate Guide to Heavy Machinery Moving EquipmentNewsAug.04,2025

-

The Evolution of Large Equipment MoversNewsAug.04,2025

-

Maximizing Efficiency with PML Magnetic Lifters in Industrial OperationsNewsAug.04,2025

-

Choosing the Best Small Gantry CraneNewsAug.04,2025

-

Innovations in Permanent Lifting Magnet TechnologyNewsAug.04,2025

-

How to Maintain Your Adjustable Gantry Crane for LongevityNewsAug.04,2025

-

PML 6 Lifting Magnet Troubleshooting GuideNewsJul.25,2025