jib gantry crane

The Jib Gantry Crane A Versatile Solution in Industrial Material Handling

The jib gantry crane stands out as an essential piece of equipment in various industrial settings, offering versatility and efficiency in material handling. Its unique design, which integrates a jib arm mounted on a gantry structure, allows it to maneuver heavy loads with precision and ease, making it a preferred choice for many businesses involved in manufacturing, construction, and logistics.

Understanding Jib Gantry Cranes

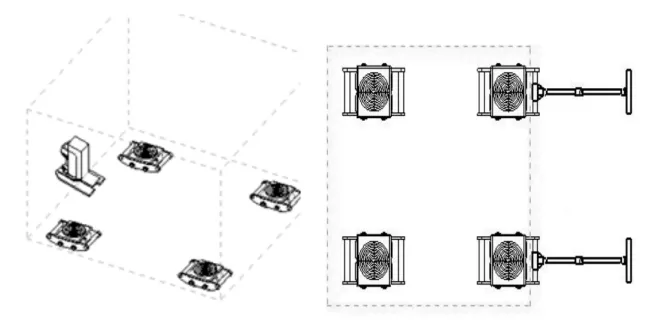

A jib gantry crane consists of a horizontal beam (the jib), a vertical or inclined support structure (the gantry), and a hoisting mechanism. This assembly provides the crane with the capability to lift, move, and lower loads in a controlled manner. The jib is typically equipped with a trolley that can travel along the beam, enhancing the crane's range of motion. The overall structure is mounted on wheels or rails, allowing it to traverse along predefined paths within a workspace.

Applications

Jib gantry cranes are widely utilized in various applications, including

1. Manufacturing Facilities In factories where heavy machinery parts or components are produced, jib gantry cranes facilitate the movement of these items between production lines and storage areas. Their precision in load handling minimizes the risk of damage during transportation.

2. Construction Sites During construction projects, these cranes are instrumental in lifting building materials, tools, and equipment to different levels of the structure. Their ability to operate in tight spaces makes them ideal for urban construction areas where conventional cranes might be impractical.

3. Shipping and Logistics Jib gantry cranes play a crucial role in loading and unloading cargo containers at docks and warehouses. Their mobility enables efficient management of goods, reducing turnaround times and enhancing overall productivity.

4. Maintenance and Repair In workshops or maintenance facilities, jib gantry cranes are employed to lift heavy machinery for repairs or inspections. This application not only increases safety by reducing the manual handling of loads but also streamlines maintenance processes.

jib gantry crane

Advantages

The advantages of jib gantry cranes are numerous, making them a go-to option for many industries

- Versatility Their design allows for adjustments in height and outreach, enabling them to handle a variety of load sizes and types. - Space Efficiency Unlike traditional overhead cranes that require extensive structural modifications, jib gantry cranes can be used in confined spaces without extensive installation requirements, saving both time and cost.

- Cost-Effectiveness Compared to larger cranes, jib gantry cranes are generally more affordable, making them accessible to small and medium-sized enterprises looking to improve their material handling processes.

- Ease of Use Operability is straightforward, allowing operators to quickly adapt and efficiently manage workloads without extensive training.

Safety Considerations

While jib gantry cranes offer numerous advantages, safety must always be a priority. Operators should adhere to proper training protocols and regularly inspect the crane for any signs of wear or mechanical failure. Implementing safety measures such as load limits, emergency stop functions, and clear communication during operation can significantly reduce the risk of accidents.

Conclusion

The jib gantry crane is a crucial tool in modern industry, offering flexibility and efficiency in material handling. Its ability to safely lift and transport heavy loads in various environments makes it indispensable in manufacturing, construction, and logistics. As industries continue to evolve, the jib gantry crane is likely to remain a favored choice for enhancing productivity and ensuring safe operations within workplaces. With ongoing advancements in technology, these cranes will undoubtedly become even more efficient and user-friendly, further solidifying their place in industrial applications.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025