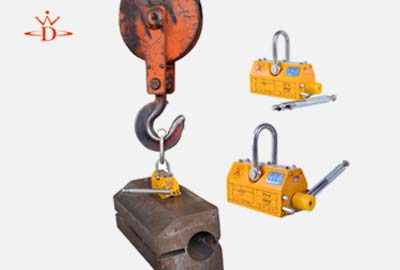

Powerful Lifting Magnet Designed for Heavy Loads Up to 100kg Capacity

Understanding Lifting Magnets The 100kg Capacity

Lifting magnets have become a crucial tool in industries that require the handling of heavy materials, particularly in manufacturing and construction. One of the most sought-after specifications in the field is the 100kg lifting capacity. This article explores the functionality, advantages, and applications of 100kg lifting magnets, alongside some important considerations for their use.

What is a Lifting Magnet?

A lifting magnet is an apparatus that uses the principles of electromagnetism to lift and move ferromagnetic materials such as iron and steel. These magnets work by creating a magnetic field when an electric current passes through the coil of wire within the device. The result is a powerful lifting capability, making them ideal for transporting heavy materials. The 100kg capacity refers to the maximum weight the magnet can safely lift under optimal conditions.

How Do Lifting Magnets Work?

The operation of lifting magnets involves several key components. At the core is the solenoid, a coil of wire that, when energized, generates a magnetic field. The magnet is equipped with an on/off switch, allowing operators to control the magnetic force. When the magnet is turned on, it attracts ferromagnetic materials, enabling them to be lifted with ease. Once the object is in place, turning off the magnet releases the hold, allowing the item to be safely deposited.

Advantages of Lifting Magnets

The benefits of using lifting magnets with a 100kg capacity are numerous. Firstly, they enhance efficiency by significantly speeding up the material handling process. Traditional methods of lifting heavy items require manual labor or machine assistance, both of which can be time-consuming and labor-intensive. Lifting magnets, on the other hand, can quickly and effortlessly move large weights, increasing productivity in the workplace.

Secondly, lifting magnets contribute to improved safety. By minimizing manual handling, the risk of injury to workers is significantly reduced. Heavy lifting can lead to strains, sprains, and other injuries; therefore, utilizing machinery that simplifies these tasks plays an essential role in promoting a safer working environment.

lifting magnet 100kg

Another advantage is the versatility of lifting magnets. They can be used in various applications, including scrap metal recycling, construction, and manufacturing industries. The capability to lift sheets of steel, pipes, and other materials makes them an invaluable asset in warehouses and factories.

Applications of 100kg Lifting Magnets

Lifting magnets are widely used across several sectors. In construction, they are used to hoist steel beams and other components. In manufacturing, they facilitate the assembly of parts and the movement of heavy machinery. Additionally, in recycling operations, 100kg magnets are employed to efficiently separate ferrous metals from non-ferrous materials, streamlining the recycling process.

In automotive manufacturing, where precision and speed are critical, lifting magnets help in assembling vehicles more efficiently. The ability to quickly position metal parts makes the production line not only faster but also more organized.

Considerations and Best Practices

While 100kg lifting magnets present numerous advantages, there are crucial considerations to ensure their effective and safe use. Operators must be trained to understand the limitations and operational guidelines of the magnets. For instance, the lifting capacity may be contingent upon the type of material being lifted and the surface conditions. Moreover, consistent maintenance and inspections are necessary to ensure the reliability of the lifting magnets.

It is also essential to evaluate the power supply, as the operation of an electromagnet depends on a stable electrical current. Any fluctuations may compromise the lifting capacity or the ability to disengage safely.

Conclusion

Lifting magnets with a 100kg capacity represent a significant advancement in the world of material handling. Their efficiency, safety, and versatility make them indispensable in many industries. By understanding their functionality and operating practices, businesses can leverage these tools to improve productivity while ensuring the safety of their workforce. As technology continues to evolve, the role of lifting magnets is likely to expand, underscoring their importance in modern manufacturing and logistics.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025