lifting magnets for steel plate

Lifting Magnets for Steel Plates Enhancing Efficiency and Safety in Industrial Operations

In the realm of heavy industry, the transportation, manipulation, and placement of steel plates are fundamental tasks that require both precision and safety. One of the most effective tools for handling steel plates is the lifting magnet. These industrial magnets have revolutionized the way steel is moved, particularly in environments like manufacturing plants, warehouses, and construction sites. This article explores the advantages, types, and considerations involved in using lifting magnets for steel plates.

Understanding Lifting Magnets

Lifting magnets, often referred to as electromagnets, utilize the principle of electromagnetism to lift heavy steel objects with ease. When electrical current flows through the coil of wire wrapped around the magnet, it generates a magnetic field strong enough to attract and hold steel plates. There are typically two main types of lifting magnets permanent lifting magnets and electromagnetic lifting magnets.

Permanent Lifting Magnets

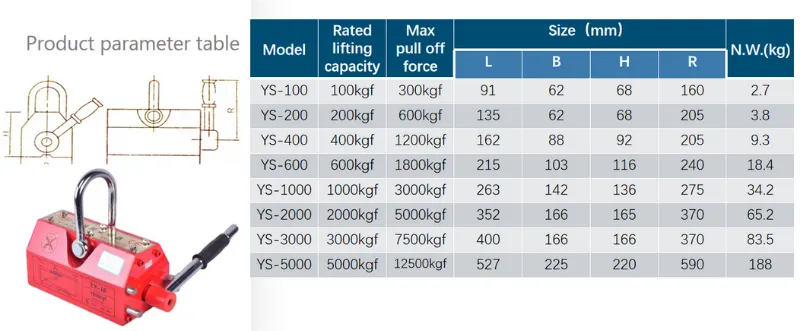

Permanent lifting magnets rely on a permanent magnet made from materials like neodymium or ferrite, which provides a consistent magnetic field without the need for electricity to maintain it. These types of magnets are lightweight, portable, and can be used in various applications. However, their lifting capacity is limited compared to electromagnetic lifting magnets, making them more suitable for smaller or lighter steel plates.

Electromagnetic Lifting Magnets

Electromagnetic lifting magnets, on the other hand, offer a higher lifting capacity and greater versatility due to their adjustable magnetic field. Operators can easily turn the magnet on or off, which is essential when needing to release a load safely and quickly. This type of magnet is ideal for heavy steel plates and can handle significant weights, making it a popular choice in industries requiring heavy lifting.

Benefits of Using Lifting Magnets

lifting magnets for steel plate

1. Efficiency One of the primary advantages of lifting magnets is their ability to streamline operations. They can lift and move heavy steel plates quickly, reducing the time and labor required for manual handling. This efficiency can lead to increased productivity on the shop floor.

2. Safety Lifting heavy steel plates can pose severe risks to workers. The use of lifting magnets minimizes the potential for injuries associated with manual lifting or the use of traditional lifting devices like hooks and slings. Because lifting magnets securely hold the load, they also reduce the risk of dropping materials, which could lead to accidents or equipment damage.

3. Versatility Lifting magnets can be used to handle various steel plate sizes and shapes. With different models available, operators can select magnets specifically designed for their unique applications, making them a versatile addition to any material handling operation.

4. Reduced Wear and Tear Traditional lifting methods often cause wear and tear on both the equipment and the steel plates themselves. Lifting magnets minimize contact with the load and reduce the risk of scratches or dents, preserving the integrity of the materials being handled.

Considerations When Using Lifting Magnets

While the benefits of lifting magnets are clear, there are important considerations to ensure their effective use. Operators must select the right lifting magnet based on the weight and thickness of the steel plates. It is also crucial to assess the condition of the plates; rust or debris can impede the magnetic connection.

Furthermore, training is essential for operators to understand how to use lifting magnets safely and effectively. Regular maintenance checks are also necessary to ensure the magnets function correctly and safely.

Conclusion

Lifting magnets for steel plates represent a significant advancement in industrial lifting technology. Their ability to enhance efficiency while improving safety makes them an indispensable tool in various sectors. As industries continue to adopt innovative lifting solutions, lifting magnets stand out for their effectiveness, versatility, and reliability, ensuring that operations remain productive and safe in today's demanding environments. Investing in lifting magnets can ultimately lead to savings in time, costs, and personnel safety, making them a wise choice for any business handling steel plates.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025