lifting magnet with release

Understanding Lifting Magnets with Release Mechanisms

Lifting magnets play an indispensable role in industries where heavy lifting and material handling are routine. These powerful tools utilize electromagnetic force to lift ferrous materials, ticking all the boxes for efficiency, precision, and safety. Among the various types of lifting magnets available in the market, the lifting magnet with a release mechanism stands out due to its advanced functionality and ease of use.

What is a Lifting Magnet?

A lifting magnet is an electromagnetic device that generates a magnetic field strong enough to lift heavy metal objects. There are various designs, including permanent magnets and electromagnets, with the latter being more commonly used in industrial applications. The fundamental principle behind lifting magnets is simple when an electric current flows through the coil of wire, a magnetic field is created, allowing the device to pick up ferromagnetic materials.

The Release Mechanism

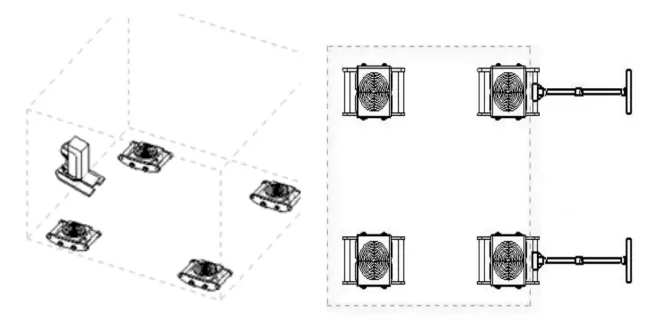

The release mechanism is a critical component of a lifting magnet. It allows operators to safely and effectively release the load once it has been lifted and transported to its intended location. This feature is especially important in industrial settings where materials need to be moved between different stations without manual handling.

A common type of release mechanism is an electric switch or a pneumatic system connected to the lifting magnet. When the operator wants to release the load, they activate the switch or the pneumatic button, which deactivates the magnetic field. This instantaneous release ensures that the load can be placed accurately and safely without risking accidents that could arise from manual release.

lifting magnet with release

Applications of Lifting Magnets with Release Mechanisms

Lifting magnets with release mechanisms are prevalent in various industries, including manufacturing, construction, and recycling. In manufacturing settings, they are often used for lifting steel plates and bars. The efficiency of handling large metallic pieces is significantly increased, as the lifting magnet can lift heavy items quickly without the need for additional machinery or manpower.

In construction, these magnets are utilized to lift and position steel beams and other metal components, ensuring that heavy materials can be placed accurately and safely. Similarly, in recycling facilities, lifting magnets are employed to separate ferrous metals from non-metal wastes, significantly enhancing operational efficiency.

Safety Considerations

While lifting magnets are powerful and highly efficient, they also pose specific safety risks. It is crucial for operators to be trained in safe handling practices and to use the equipment as intended. Regular inspection and maintenance of both the magnets and the release mechanisms are essential to ensure reliability. Operators should follow manufacturer guidelines to prevent accidents that could arise from worn-out or malfunctioning equipment.

Conclusion

Lifting magnets with release mechanisms represent a significant advancement in material handling technology. They offer enhanced effectiveness in moving heavy loads while ensuring safety and precision. Their applications in various industries underline their versatility and indispensable role in modern operations. As industries continue to evolve, the integration of advanced lifting magnet technologies is likely to grow, driving efficiency and safety to new heights. Proper training, maintenance, and adherence to safety protocols will further enhance the benefits of these powerful tools, solidifying their place in the future of industrial automation.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025