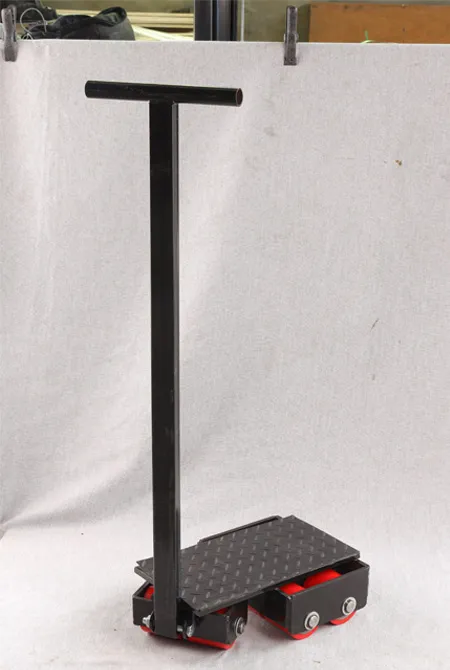

light gantry crane

Understanding Light Gantry Cranes A Key Tool in Modern Industry

Light gantry cranes have gained significant traction in various industrial applications due to their versatility, efficiency, and ease of use. These cranes are particularly beneficial in situations where space is limited and precise maneuverability is required. Understanding what light gantry cranes are and how they can be effectively utilized can greatly enhance operational efficiency in a myriad of settings.

A light gantry crane consists of a bridge that spans the width of the workspace, supported on two or more legs. It is designed to lift and move loads horizontally across a designated area. Unlike traditional overhead cranes, light gantry cranes are more compact and can be used both indoors and outdoors. They are typically constructed from lightweight materials, which makes them easier to transport and set up, while still maintaining sufficient strength to handle substantial loads.

One of the distinguishing features of light gantry cranes is their modular design. This allows for flexibility in configuration, enabling users to easily adjust the crane's height and span to accommodate specific needs. Depending on the application, light gantry cranes can be fitted with various hoists and lifting mechanisms, ranging from electric winches to manual chain hoists. This adaptability makes them suitable for a diverse range of tasks, from lifting automotive parts in a workshop to moving equipment in a warehouse.

Safety is a paramount consideration in any lifting operation, and light gantry cranes are designed with numerous safety features

. Most models are equipped with overload protection systems that prevent the crane from lifting loads beyond its capacity, reducing the risk of accidents. Additionally, operators are often required to undergo training to ensure safe and proficient handling of the equipment, which further minimizes workplace hazards.light gantry crane

In terms of operational efficiency, light gantry cranes drastically reduce the time and labor required to move heavy items. They allow for quick adjustments and repositioning, which can help streamline workflows in manufacturing and assembly environments. The ease of use and mobility of these cranes also means that less manpower is often needed, which can lead to cost savings over time.

Moreover, the installation and maintenance of light gantry cranes are relatively straightforward compared to more complex lifting systems. Many models do not require permanent installation, which can be advantageous for companies that need to frequently rearrange their workspace. Regular maintenance schedules are also easy to manage, ensuring that the cranes remain in optimal working condition without incurring significant downtime.

As industries continue to evolve and adapt to the demands of modern day operations, the role of light gantry cranes will likely become even more prominent. Their ability to enhance productivity while maintaining safety standards makes them an indispensable tool in manufacturing, construction, warehousing, and many other sectors. For any business looking to improve their material handling processes, investing in a light gantry crane could prove to be a strategic move that drives efficiency and growth.

In conclusion, light gantry cranes embody a blend of practicality, safety, and innovation. They not only facilitate the smooth movement of goods and materials but also contribute to a more organized and efficient workspace. Whether in a bustling factory or a small workshop, these cranes are proving to be an invaluable asset in modern industrial operations.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025