Compact Gantry System for Efficient Material Handling and Transport Solutions

Exploring the Concept of a Lightweight Gantry

The evolution of industrial machinery has led to the development of various innovative solutions aimed at increasing efficiency, flexibility, and safety in manufacturing and construction environments. One such innovation is the lightweight gantry, which has gained significant attention due to its versatility and functionality.

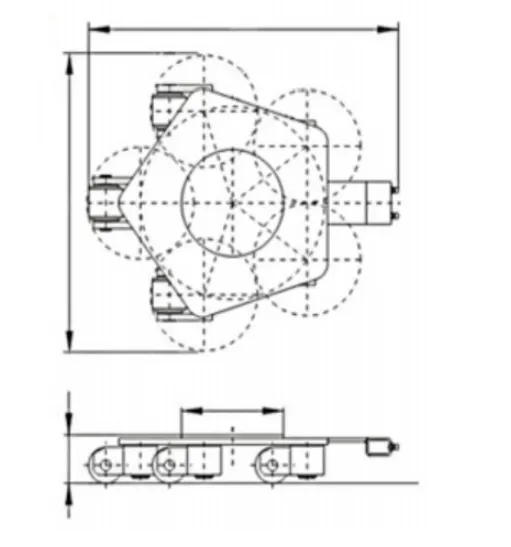

A gantry, traditionally used in manufacturing settings, serves as a framework that supports heavy machinery, such as hoists or cranes, allowing for the movement of materials across a workspace. The introduction of lightweight materials and designs has transformed the gantry system, making it not only easier to handle but also more cost-effective for businesses looking to optimize their operations.

The primary advantage of a lightweight gantry is its portability. Unlike conventional gantries, which can be cumbersome and may require extensive installation, lightweight options are often designed for easy assembly and disassembly. This feature allows for quick deployment in various locations, making it ideal for projects that require mobility and flexibility. For instance, in construction sites where space is limited and adaptability is crucial, lightweight gantries can be easily transported and set up to meet changing requirements.

In addition to portability, these gantries offer enhanced safety features. Traditional heavy gantries can pose risks during setup and operation due to their weight and size. Lightweight varieties mitigate these risks by minimizing the manual handling required and reducing the possibility of accidents related to heavy lifting. Many modern lightweight gantries also incorporate safety mechanisms, such as locking systems and stability features, ensuring safe usage even in demanding environments.

lightweight gantry

The materials used in constructing lightweight gantries play a significant role in their overall effectiveness. Manufacturers are now utilizing advanced composites, aluminum alloys, and other high-strength yet lightweight materials that provide durability without the excessive weight. This shift in material usage not only improves the structural integrity of the gantry but also enhances its load-bearing capacity while keeping operational costs low.

From a design perspective, lightweight gantries are often customizable to suit specific applications. Whether it’s for automotive assembly, warehouse operations, or even artistic installations, these gantries can be tailored to accommodate diverse needs. This customization aspect makes them an attractive option for various industries, allowing for specialized configurations that deliver optimal performance.

Moreover, the rise of automation in industries has paved the way for lightweight gantries to integrate seamlessly with robotic systems. This integration enhances productivity further, as these gantries can support automated equipment that requires precision and stability during operations. As industries move towards greater automation, the demand for adaptable and lightweight solutions will likely continue to grow.

In conclusion, the lightweight gantry represents a significant advancement in the realm of material handling and mobility solutions. By combining portability, safety, durability, and customization, these innovative structures are revolutionizing how industries approach their lifting and transportation needs. As technology continues to evolve, we will likely see even more sophisticated designs that further expand the capabilities and applications of lightweight gantries, making them indispensable tools in modern manufacturing and construction landscapes.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025