Selecting the Perfect Casters for Smooth Machine Mobility and Enhanced Performance

The Versatility and Importance of Machine Moving Casters

In the modern industrial landscape, efficiency and mobility are paramount for successful operations. One of the unsung heroes contributing to this efficiency is the machine moving caster. These essential components, often overlooked, are crucial for the seamless movement of machinery and equipment, enhancing productivity across various sectors.

What Are Machine Moving Casters?

Machine moving casters are wheeled devices attached to the base of machinery or equipment, enabling it to be relocated with ease. They come in various sizes, materials, and designs, catering to diverse applications from light-duty tasks in offices to heavy-duty operations in factories. The versatility of these casters makes them indispensable in many settings, facilitating the quick repositioning of equipment, which is vital for workflow optimization.

Key Advantages of Using Machine Moving Casters

1. Enhanced Mobility The primary function of machine moving casters is to enhance mobility. Equipment that is traditionally bulky and cumbersome can be easily moved without the need for strenuous physical labor or the use of lifting equipment. This ease of movement is particularly beneficial in dynamic environments where space management is critical.

2. Operational Efficiency Casters allow for quick adjustments in the layout of machinery and equipment, facilitating better workflow and reducing downtime. When production lines need reconfiguration or when equipment must be moved for maintenance, machine moving casters save valuable time and resources.

3. Safety Improvements Moving heavy machinery poses a significant safety risk. Machine moving casters reduce the risk of injury by minimizing the physical effort needed to relocate equipment. Moreover, most casters are designed with safety features such as brakes, preventing unwanted movement and enhancing overall workplace safety.

machine moving casters

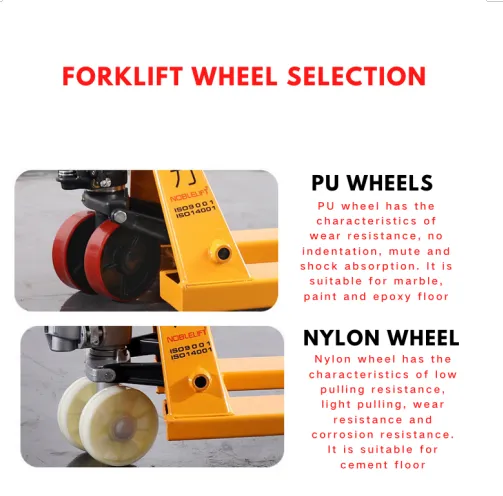

4. Versatility Available in various materials such as rubber, plastic, and metal, machine moving casters can be tailored to suit specific needs. For instance, rubber casters are excellent for indoor use, providing quiet movement and protecting floors, while metal casters can handle heavier loads in more robust conditions.

5. Load Capacity Casters come with varying load capacities, enabling their use in both light-duty and heavy-duty applications. It’s vital for businesses to select the right type of caster based on the weight and nature of the equipment being moved, ensuring that the casters can handle the load without compromising safety or efficiency.

Applications Across Industries

The applications for machine moving casters are vast and varied. In a manufacturing setting, assemblies and machines can be repositioned to optimize floor layouts. In hospitals, mobile medical equipment can be easily moved from one room to another, streamlining patient care. In warehouses, product shelves can be adjusted and relocated, improving space utilization and workflow.

Choosing the Right Caster

Selecting the right machine moving caster is crucial for ensuring optimal performance. Factors to consider include the weight capacity, surface material, wheel diameter, and any specific environmental conditions (such as exposure to moisture or chemicals). Additionally, businesses should evaluate whether swivel casters or fixed casters are more appropriate for their needs.

Conclusion

Machine moving casters are a cornerstone of efficiency in operations across numerous industries. By enhancing mobility, improving workflow, and ensuring safety, they play an essential role in modern workplaces. As businesses continue to strive for greater productivity, the importance of machine moving casters cannot be overstated. Investing in the right types of casters not only facilitates the smooth operation of equipment but also contributes to a safer, more dynamic work environment. Whether in a factory, a hospital, or an office, these small but mighty tools help propel industries towards greater success.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025