Heavy Equipment Transport and Setup Solutions for Complex Projects and Industrial Needs

Understanding Machine Moving and Rigging A Comprehensive Guide

Machine moving and rigging is a critical aspect of various industries, particularly in manufacturing, construction, and logistics. As machinery becomes more complex and larger in scale, the need for specialized skills and equipment to safely move and position these machines is essential. This article explores the key elements, techniques, and safety protocols involved in machine moving and rigging.

What is Machine Moving and Rigging?

Machine moving refers to the process of relocating heavy equipment or machinery from one location to another. Rigging, on the other hand, involves the use of equipment such as ropes, chains, and hoists to lift and secure loads during transport. Together, machine moving and rigging encompass a set of practices designed to ensure that heavy machinery is moved safely and efficiently, minimizing the risk of damage to both the equipment and the surrounding environment.

Importance of Professional Services

While it may be tempting for businesses to use in-house resources for machine moving, hiring professional services is often the best solution. Professional riggers and movers bring expertise and specialized equipment that ensure the job is done correctly. They are trained in the principles of load balancing, weight distribution, and secure lifting techniques. Moreover, they understand the risks associated with moving heavy machinery and implement safety measures to prevent accidents.

Techniques Used in Machine Moving and Rigging

1. Planning and Preparation The first step in machine moving involves thorough planning. This includes assessing the machinery's weight, dimensions, and the environment of both the current and destination locations. Site assessments help identify potential obstacles such as doorways, ceilings, and other structures that may hinder the move.

2. Selecting the Right Equipment Depending on the machinery’s weight and size, the right equipment must be chosen. This may include cranes, forklifts, dollies, or hydraulic jacks. The choice of equipment depends on factors like lifting capacity, reach, and maneuverability.

3. Safe Rigging Practices Rigging involves using slings, chains, and other devices to hoist loads safely. Proper rigging techniques ensure that the load is stable and secure during transport. Riggers must calculate the load’s center of gravity and use appropriate lifting points to maintain balance.

machine moving & rigging

4. Lifting and Moving Once rigging is set, the actual movement can begin. It is crucial for the moving team to communicate effectively throughout this process. Use of hand signals or radios can help ensure that everyone is aware of the ongoing operations.

5. Positioning After moving the machinery to its destination, careful positioning is necessary. This may involve leveling the machinery and securing it in place to prevent any unintended movement.

Safety Protocols in Machine Moving and Rigging

Safety is paramount in machine moving and rigging. Here are some essential safety protocols

- Personal Protective Equipment (PPE) All team members should wear PPE, including helmets, gloves, and safety shoes, to minimize the risk of injuries.

- Safety Briefings Before commencing any operation, a safety briefing should be held to review the plan, roles, and potential risks involved.

- Load Testing Regular testing of rigging equipment is necessary to ensure that it meets safety standards and is free from wear and tear.

- Monitoring and Supervision An experienced supervisor should oversee the process to ensure that all safety protocols are adhered to and that any arising issues are addressed promptly.

Conclusion

Understanding machine moving and rigging is crucial for the successful relocation of heavy machinery. By adhering to proper techniques, utilizing professional services, and prioritizing safety, businesses can minimize risks and enhance efficiency. As industries continue to evolve with complex machinery, the significance of skilled rigging and moving will only increase, highlighting the need for continuous training and development in this field. Investing in professional services for machine moving and rigging not only protects the equipment but also safeguards the workforce, ultimately contributing to the overall success of projects across various sectors.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

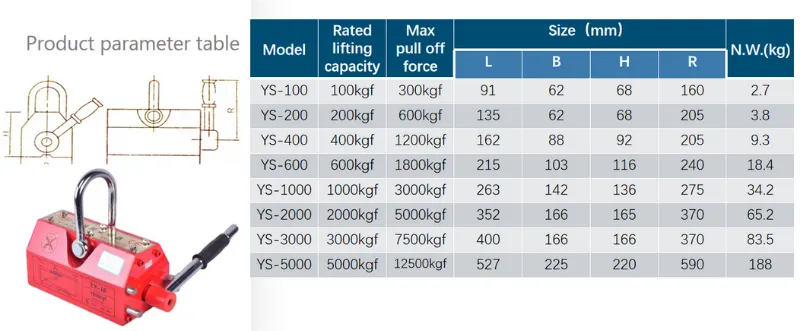

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025