machine moving rollers

The Role of Machine Moving Rollers in Modern Industry

In the realm of manufacturing and logistics, machine moving rollers have emerged as indispensable tools that enhance efficiency and safety. These devices, often referred to simply as moving rollers or conveyor rollers, facilitate the effortless movement of heavy machinery and materials across various operational settings. Their significance cannot be overstated, as they contribute to streamlined processes and improved productivity in numerous industries, including construction, warehousing, and automotive manufacturing.

Machine moving rollers come in various designs, each suited for specific applications. The most common types include gravity rollers, powered rollers, and skate rollers. Gravity rollers, for instance, rely on gravitational force to move items downhill, making them ideal for assembly lines where products need to flow smoothly from one workstation to another. Powered rollers, on the other hand, are driven by electric motors and provide controlled movement, making them suitable for more complex operations where precise positioning is crucial.

One of the primary benefits of using moving rollers in industrial settings is the reduction of manual labor. Traditionally, moving heavy machinery or pallets required significant human effort, often leading to fatigue and potential injuries. By utilizing machine moving rollers, companies can minimize the physical strain on their workforce. Instead of manually lifting and shifting loads, employees can simply guide the items on the rollers, thereby enhancing safety and reducing the risk of workplace accidents.

Moreover, machine moving rollers can greatly enhance operational efficiency. In environments where time is of the essence, these rollers allow for quick and seamless transportation of goods. For instance, in a manufacturing plant, integrating moving rollers into the assembly line can significantly decrease the time taken to move components from one station to the next. This can lead to faster production cycles and, ultimately, higher output.

machine moving rollers

The versatility of moving rollers is another key advantage. They can be utilized in various configurations to suit different spaces and workflows. For instance, they can be installed in straight runs, curves, or even inclined planes, adapting easily to the layout of the facility. Additionally, they can handle a wide range of materials, from lightweight packages to cumbersome machinery, making them a flexible solution for diverse industries.

When considering the environmental impact, machine moving rollers can also contribute to sustainability efforts. By enabling more efficient handling and transportation of materials, they can reduce energy consumption associated with moving heavy loads. This aligns with the growing emphasis on environmentally friendly practices in industries worldwide.

However, like any machinery, moving rollers require proper maintenance to ensure they function effectively and safely. Regular inspections, lubrication, and timely replacement of worn-out parts are crucial to preventing breakdowns and extending the lifespan of these devices. Furthermore, training employees on the correct usage and maintenance protocols for the rollers can enhance safety and operational efficiency.

In conclusion, machine moving rollers are a critical component of modern industrial processes. They not only improve efficiency and safety but also reduce the physical burden on workers while supporting diverse operational needs. As industries continue to evolve and embrace technological advancements, the importance of these moving rollers will only continue to grow, making them an integral part of the future of manufacturing and logistics.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

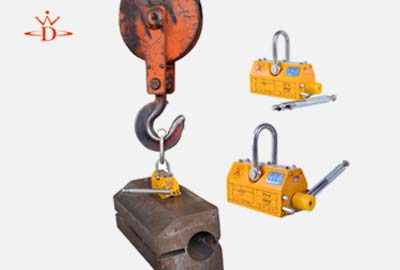

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025