Efficient Strategies for Relocating Industrial Machinery and Equipment

The Essentials of Machinery Relocation A Comprehensive Guide

Machinery relocation is a critical process in various industries, whether for upgrading equipment, moving to a new facility, or optimizing factory layouts. This intricate task requires meticulous planning and execution, as it can significantly impact production efficiency, safety, and operational costs. Understanding the key elements of machinery relocation can help businesses navigate this complex process more effectively.

Planning Phase

The first step in any successful machinery relocation is thorough planning. This involves assessing the machinery being moved, understanding its specifications, and determining the best method for relocation. An inventory of all equipment should be created, noting any special handling requirements due to weight, size, or fragility.

Additionally, businesses should evaluate the new location’s infrastructure to ensure it can accommodate the machinery. This includes analyzing floor load capacities, accessibility, and the presence of necessary utilities such as power and water supply.

Risk Assessment and Management

Once the planning is underway, conducting a risk assessment is crucial. This involves identifying potential hazards associated with the relocation process and implementing strategies to mitigate them. Common risks include machinery damage, safety incidents, and operational downtime. By anticipating these risks, companies can develop contingency plans that safeguard against potential issues.

Logistical Considerations

Logistics play a vital role in machinery relocation. Choosing the right transport method—whether by road, rail, or sea—depends on the machinery's size, weight, and distance to the new site. Specialized equipment, such as cranes or forklifts, may be required to lift and move large machines.

Coordination with specialist movers who have experience in machinery relocation can streamline the process, ensuring that the right equipment is on hand when needed

. It is essential to create a timeline for the move, which should detail each phase of the relocation process to avoid unnecessary delays.Disassembly and Packing

machinery relocation

Before transportation, machinery often needs to be disassembled. This requires skilled technicians who understand the equipment's intricacies. Proper disassembly ensures that all parts are moved safely and minimizes the risk of damage during transit.

Furthermore, using appropriate packing materials is vital. Items should be cushioned and secured to prevent movement during transport. Clear labeling of all pieces will aid in the reassembly process at the new location.

Reassembly and Installation

Upon arrival at the new site, the relocation process shifts to reassembly. This is where the previous planning and preparation pay off. Technicians should follow documented procedures for reassembly, ensuring that machines are set up correctly and efficiently. Calibration and testing should be performed to confirm that machinery operates as intended before resuming normal operations.

Training and Transition

Once the machinery is installed and operational, employee training becomes critical. Workers should be familiarized with any new equipment or updated processes resulting from the relocation. Additionally, initial time for testing and adjustments can ensure a seamless transition back to standard production schedules.

Monitoring and Evaluation

Finally, after the machinery relocation is complete, it's important to monitor the performance and evaluate the process. Understanding what worked well and what could be improved will aid future relocation projects and enhance overall operational efficiency.

Conclusion

Machinery relocation is a multifaceted endeavor that requires careful consideration and execution. By following best practices during planning, risk assessment, logistics management, disassembly, reassembly, and training, businesses can achieve a successful relocation that minimizes downtime and maximizes productivity. Understanding the intricacies of this process is essential for any organization looking to optimize its operations and ensure smooth transitions in an ever-evolving industrial landscape.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

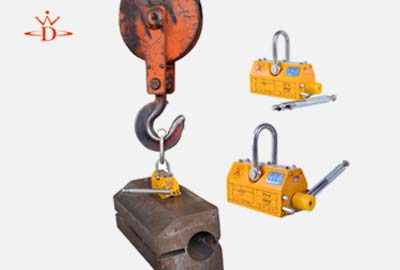

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025