machinery rollers

Understanding Machinery Rollers A Key Component in Various Industries

Machinery rollers are essential components utilized in numerous industries, playing a critical role in facilitating movement, transportation, and operation of machinery. From manufacturing plants to construction sites, these rollers, which come in various shapes, sizes, and materials, are designed to perform specific functions that enhance productivity and efficiency.

At its core, a roller is a cylindrical component that rotates around an axis, allowing for smooth motion across surfaces. In industrial applications, machinery rollers are primarily used in conveyor systems, which are vital for the transportation of materials and products. These systems streamline the movement of goods, eliminating the need for manual handling and significantly reducing the risk of injury. The efficiency of a conveyor system is heavily reliant on the quality and design of the rollers in use.

One of the most common types of machinery rollers is the conveyor roller. These rollers can be found in various configurations, including gravity rollers and powered rollers. Gravity rollers rely on the force of gravity to move items along the conveyor, which is ideal for lightweight materials. In contrast, powered rollers utilize a motor to drive the movement, making them suitable for heavier loads. The choice between these two types depends on the specific needs of the operation, highlighting the importance of selecting the right roller for the task at hand.

machinery rollers

In addition to conveyor rollers, other types of machinery rollers include drum rollers, idler rollers, and tapered rollers

. Drum rollers are often used in compaction equipment, where they help in leveling and consolidating surfaces, particularly in construction projects. Idler rollers, on the other hand, are utilized to support the belt in a conveyor system, ensuring proper tension and alignment. Tapered rollers are commonly found in bearings and axles, providing better load distribution and reducing friction, which enhances the overall lifespan and efficiency of the machinery.The materials used to manufacture machinery rollers are diverse, with common options including steel, plastic, and rubber. Steel rollers are renowned for their strength and durability, making them ideal for heavy-duty applications, while plastic rollers are often chosen for their lightweight properties and resistance to corrosion. Rubber rollers, known for their shock absorption capabilities, are frequently used in environments where minimizing vibration is crucial. This variety allows industries to choose the most appropriate roller for their specific application, balancing cost, performance, and longevity.

Innovations in roller technology have led to the development of advanced features such as self-lubricating properties and increased load-bearing capacities. These advancements further improve the performance of machinery rollers, ensuring they can withstand the rigors of modern industrial environments. Furthermore, regular maintenance and timely replacement of worn rollers are essential practices that can significantly extend the lifespan of machinery and enhance overall operational efficiency.

In conclusion, machinery rollers are an integral part of many industrial applications, serving critical functions that enhance productivity and efficiency. Understanding the different types of rollers, their applications, and materials can help industries make informed decisions that align with their operational needs. As technology continues to evolve, we can expect further advancements in roller design and functionality, paving the way for safer, more efficient, and more productive industrial environments.

-

Portable 2000 lb Gantry Crane | Heavy-Duty & AdjustableNewsAug.30,2025

-

Versatile Lifting Solutions with Gantry and Overhead CranesNewsAug.29,2025

-

The Versatile Mobile Gantry Crane SolutionNewsAug.29,2025

-

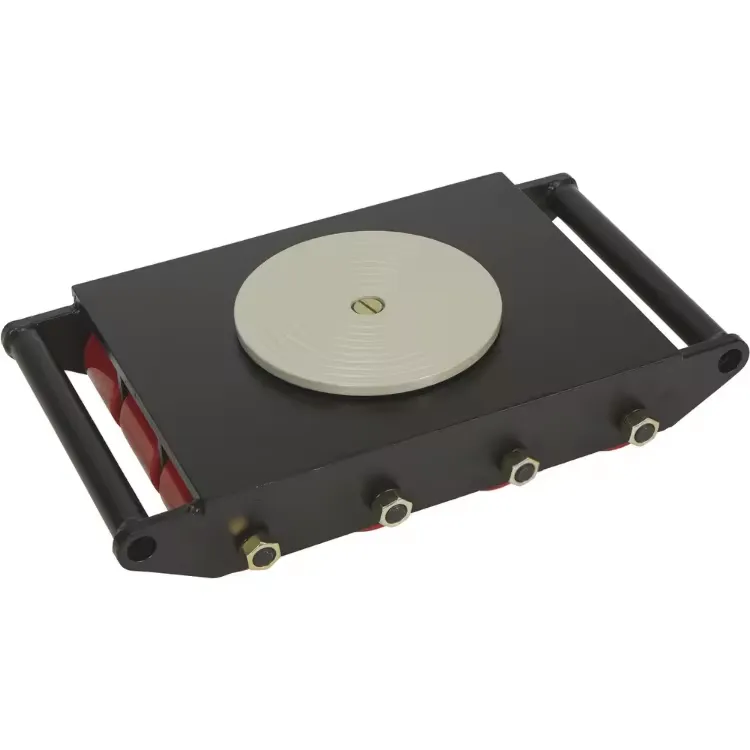

Reliable Movement with Heavy Machinery Skates and RollersNewsAug.29,2025

-

Reliable Lifting Performance with 2000 lb Gantry Crane and 2 Ton Overhead SystemsNewsAug.29,2025

-

Maximize Lifting Efficiency with PML Magnetic LiftersNewsAug.29,2025

-

Efficient Relocation Starts with Reliable Machinery MoversNewsAug.29,2025