Essential Guide to Machinery Rollers for Optimal Performance and Efficiency

Understanding Machinery Rollers Essential Components for Industrial Operations

Machinery rollers are vital components in various industrial applications, playing a critical role in the smooth operation of heavy equipment and transport systems. From conveyors to heavy-duty trucks, these rollers help facilitate movement and reduce friction, thereby increasing efficiency and productivity in various industries.

What Are Machinery Rollers?

Machinery rollers are cylindrical components that enable the movement of heavy loads across different surfaces. They are designed to bear heavy weights while providing a smooth rolling action, which minimizes resistance and wear on both the machinery and the transported materials. Rollers can be made from various materials, including steel, plastic, and rubber, each chosen based on the application's specific requirements.

Types of Machinery Rollers

There are several types of machinery rollers, each suited for different applications

1. Conveyor Rollers These are commonly used in material handling systems, where they facilitate the movement of goods along conveyor belts. Conveyor rollers can be powered or non-powered, with the former often used in automated systems to move items seamlessly.

2. Idler Rollers Idler rollers are used to support and guide conveyor belts without providing power. They help maintain belt tension and alignment, ensuring that materials are transported efficiently.

3. Drum Rollers Typically found in vehicles, drum rollers are used in the compaction of materials. They are designed to exert substantial downward force while rolling, making them effective for tasks like road construction and earthmoving.

machinery rollers

4. Heavy-Duty Rollers These are robust rollers designed for the transportation of extremely heavy materials and equipment. They often feature reinforced materials capable of withstanding significant stress and impact, making them ideal for construction and demolition sites.

The Advantages of Using Machinery Rollers

The use of machinery rollers brings several advantages

- Increased Efficiency By reducing friction, rollers allow machines to operate smoothly and with less energy, which translates to cost savings in fuel and operational expenses.

- Durability High-quality rollers are designed to withstand harsh working conditions and heavy loads, ensuring longevity and reliability.

- Versatility Rollers can be customized to fit various applications, making them suitable for diverse industries, including manufacturing, logistics, and construction.

- Safety Properly functioning rollers contribute to a safer work environment by minimizing the risk of accidents caused by equipment malfunctions or material spills.

Conclusion

In conclusion, machinery rollers are an indispensable part of many industrial processes. Their ability to facilitate movement while reducing friction and wear makes them essential for enhancing efficiency and safety in operations. As industries continue to evolve, the design and functionality of machinery rollers will likely advance, further solidifying their role in the world of heavy machinery and logistics. Understanding the types and functions of these components can help businesses make informed decisions, ultimately leading to improved productivity and operational success.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

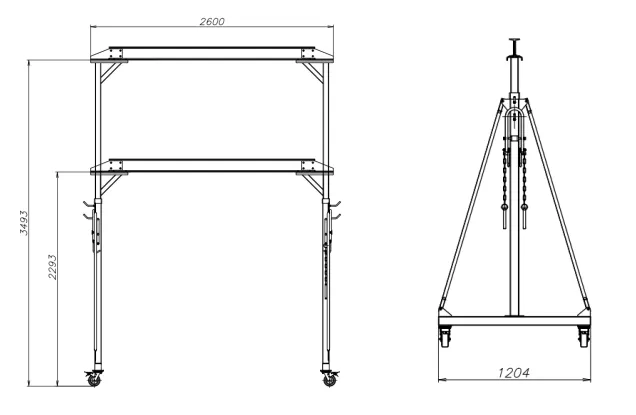

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025