machinery skate dolly

Understanding Machinery Skate Dollies A Key Tool for Heavy Lifting

When it comes to the world of heavy lifting and transportation of industrial equipment, the machinery skate dolly stands out as an essential tool. These devices, designed to facilitate the movement of large and bulky objects, are crucial in a variety of settings, from warehouses and construction sites to manufacturing plants. This article explores the design, functionality, and application of machinery skate dollies, highlighting why they are indispensable in the realm of heavy-duty lifting.

What is a Machinery Skate Dolly?

A machinery skate dolly, often referred to simply as a skate dolly, is a flat platform equipped with wheels or rollers that allow for the easy movement of heavy machinery or equipment

. These dollies come in various sizes and weight capacities, enabling them to accommodate different types of machinery, from industrial machines to large office copiers. The basic design features a sturdy frame, which is low to the ground to facilitate the loading and unloading of heavy items, combined with durable wheels that can handle substantial weight without faltering.Design Features and Types

Machinery skate dollies are engineered to be robust, with materials that resist wear and tear under heavy loads. Most dollies feature a combination of fixed and swivel wheels, providing both stability and maneuverability. The fixed wheels allow for straight movement, while the swivel wheels enable easier navigation around corners and tight spaces.

There are various types of skate dollies available in the market. Some are designed with a very low profile, perfect for very heavy machinery that needs minimal height during loading. Others come with adjustable features to provide versatility for different equipment types. Additionally, specialized dollies may have added features such as brake systems to secure the load during transport, or even hydraulic lifts that can assist in loading heavy items onto the dolly.

Advantages of Using Machinery Skate Dollies

machinery skate dolly

1. Increased Efficiency Moving heavy machinery without a skate dolly can be a slow, labor-intensive process. Dollies significantly reduce the time and effort required to move heavy items, allowing for a streamlined workflow. 2. Safety Safety is a primary concern in industrial environments. Using machinery skate dollies minimizes the risk of injury associated with lifting and carrying heavy loads. They significantly decrease the chance of accidents that can occur when multiple workers attempt to move large machinery without proper tools.

3. Cost-Effectiveness Investing in skate dollies can save companies money in the long run. By reducing the likelihood of workplace injuries, companies can lower their workers' compensation claims and improve overall productivity.

4. Versatility Skate dollies can be used in various settings. They are effective not only in moving machinery but also in transporting large furniture, crates, and even outdoor equipment. This versatility makes them a valuable asset for businesses across multiple industries.

Applications Across Industries

The usage of machinery skate dollies spans various sectors, including manufacturing, automotive, construction, and logistics. In manufacturing, skate dollies facilitate the movement of assembly-line equipment, while in the automotive industry, they help maneuver engines and other heavy parts during repairs. Construction sites utilize dollies for shifting heavy tools and structural components, ensuring that projects stay on schedule and within budget. In logistics, they aid in transport within warehouses, helping to organize and relocate inventory efficiently.

Conclusion

In conclusion, machinery skate dollies are indispensable tools for anyone involved in heavy lifting and transportation. Their thoughtful design, efficiency, and safety benefits make them a staple in various industries. By investing in high-quality skate dollies, businesses can enhance their operational capabilities, ensure worker safety, and promote a culture of efficiency and productivity. Whether in a bustling manufacturing facility or a quiet warehouse, they play a vital role in the everyday movement of heavy equipment, making them an essential part of the industrial toolkit.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

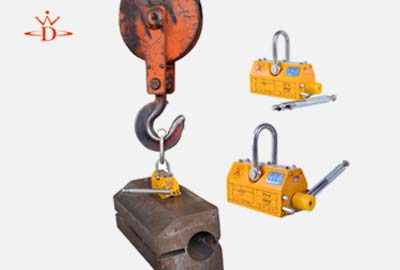

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025