Effective Methods for Transporting and Relocating Industrial Machinery and Equipment

Machine Shifting Equipment Essential Tools for Modern Industry

In today's fast-paced industrial landscape, efficiency and precision are paramount. One crucial aspect that underpins this efficiency is the effective movement and relocation of heavy machinery and industrial equipment. Machine shifting equipment plays a pivotal role in enabling businesses to optimize their production processes and enhance operational agility. This article explores the significance, types, and best practices related to machine shifting equipment.

The Importance of Machine Shifting Equipment

As industries evolve, companies often face the need to reconfigure their facilities in response to changing demands or to accommodate new machinery. This reconfiguration frequently involves moving heavy equipment, which can pose significant challenges. The right machine shifting equipment not only facilitates these moves but also ensures that the machinery is relocated without damage, maintaining productivity and safety.

The benefits of using specialized machine shifting equipment include reduced downtime, minimized risk of injury to personnel, and enhanced overall efficiency. By utilizing tools designed for moving heavy machinery, businesses can streamline operations and reduce the likelihood of costly interruptions.

Types of Machine Shifting Equipment

1. Forklifts Forklifts are perhaps the most recognized machine shifting equipment. They have the capacity to lift and transport heavy loads over shorter distances. Whether used in warehouses or on construction sites, forklifts are versatile tools that enhance the movement of machinery and materials.

2. Hydraulic Jacks Hydraulic jacks are essential for lifting heavy equipment off the ground to facilitate its movement. These tools leverage hydraulic power to lift significant weights with minimal effort, making them invaluable in machine shifting operations.

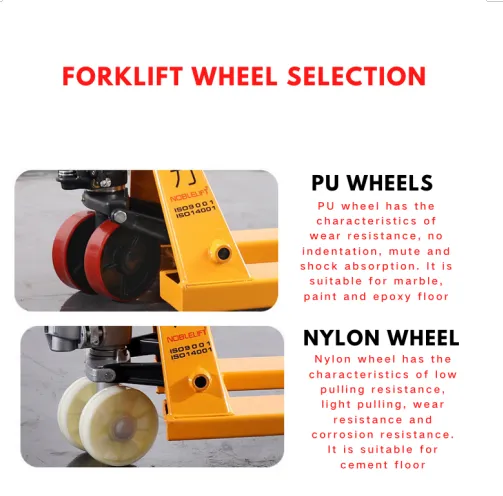

3. Pallet Jacks A staple in warehouses, pallet jacks are used to move palletized goods and equipment. They come in manual and electric versions and are vital for transporting materials around production floors or storage areas.

4. Skates and Rollers For larger machines, skates and rollers are often used. These devices allow heavy machinery to be moved more easily across flat surfaces. By distributing the weight of the equipment, skates reduce friction and make it feasible to shift equipment that would otherwise be immovable.

machine shifting equipment

5. Cranes and Hoists For extremely heavy and cumbersome equipment, cranes and hoists provide the necessary power. These machines can lift and move large items vertically and horizontally, making them indispensable in industrial environments where heavy lifting is a regular occurrence.

Best Practices for Using Machine Shifting Equipment

To maximize the effectiveness of machine shifting equipment, companies should follow several best practices

1. Assess Equipment Needs Understanding the specific equipment and its weight is crucial. Determine the size, weight, and dimensions of the machinery to select the appropriate shifting tools.

2. Regular Maintenance Regular inspections and maintenance of machine shifting equipment ensure reliability and safety. Equipment that is well-maintained is less likely to malfunction during critical operations.

3. Training Personnel It is essential to train employees on how to operate machine shifting equipment safely and efficiently. Knowledgeable staff can minimize risks and ensure that operations proceed smoothly.

4. Planning Moves Careful planning prior to any machine relocation is vital. Consideration should be given to the path of movement, potential obstacles, and the layout of the workspace to avoid issues during the shifting process.

5. Safety First Always prioritize safety. Use proper gear, and ensure that surrounding areas are clear of personnel when moving heavy equipment. Following safety protocols not only protects workers but also prevents damage to equipment.

Conclusion

In conclusion, machine shifting equipment is a fundamental component of modern industrial operations. As demands for efficiency and precision continue to rise, the ability to move and reposition machinery quickly and safely has never been more critical. By investing in the right tools and adhering to best practices, businesses can enhance their operational capabilities, ensuring they remain competitive in an ever-evolving market. The careful selection and utilization of machine shifting equipment will ultimately contribute to smoother workflows, reduced downtime, and a safer working environment.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025