machine shop equipment movers

The Importance of Professional Machine Shop Equipment Movers

In today’s fast-paced industrial environment, the success of a manufacturing operation often relies on the efficiency and precision of its machine shop. At the heart of these operations are the machines that perform critical tasks, from milling and drilling to welding and shaping. However, with the constant evolution of technology and the need for production optimization, businesses often find themselves in a position where they must relocate their machine shop equipment. This is where professional machine shop equipment movers come into play.

Understanding Machine Shop Equipment Movers

Machine shop equipment movers are specialized professionals trained to handle the logistics of moving heavy and often sensitive machinery. Unlike typical movers, these experts possess a deep understanding of industrial equipment, ensuring that machinery is not only transported safely but also reassembled and reinstalled in a new location without damage. Their service is crucial for manufacturers looking to expand, upgrade, or relocate.

The Challenges of Moving Heavy Machinery

Moving industrial equipment presents unique challenges that require expertise in rigging, lifting, and transportation. Heavy machinery can weigh several tons and may be sensitive to vibrations, requiring careful handling to maintain precision calibration. Some common challenges include

1. Weight and Size Large machines often exceed standard weight limits for transport vehicles, necessitating specialized equipment and methods for safe moving. 2. Complex Installation and Setup Many machines are not simply dropped in place but require careful positioning, leveling, and calibration, which can be technically demanding.

3. Downtime Costs In the manufacturing world, every minute that production is halted can lead to significant costs. Efficient moving processes help minimize downtime.

4. Regulatory Compliance Moving machinery may involve compliance with local regulations, including permits for oversized loads or road closures.

Benefits of Hiring Professionals

1. Expertise and Experience Professional equipment movers have the training and experience to handle a variety of machinery safely and efficiently. They are familiar with different types of equipment, from CNC machines to lathes, and know the best practices for moving them.

machine shop equipment movers

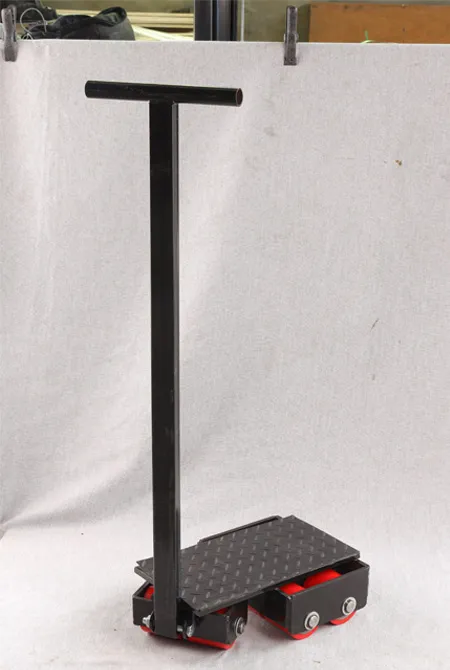

2. Proper Equipment Professional movers come equipped with specialized tools, including rigging gear, hoists, and transport vehicles designed for heavy loads. This equipment ensures that the machinery is secure during transport.

3. Safety A key advantage of hiring professionals is the commitment to safety. The risk of injury or damage is significantly reduced when trained personnel manage the move. They adhere to safety protocols that protect both the crew and the equipment.

4. Time Efficiency With a dedicated team on the job, the moving process can be completed quickly and effectively. This time efficiency translates into lowered costs and minimal production downtime.

5. Post-Move Support Many professional movers offer post-move services, which include reinstallation and calibration of machines. This additional support helps ensure that operations resume smoothly and that the equipment functions correctly from the start.

Choosing the Right Moving Company

When selecting a machine shop equipment mover, it’s essential to consider several factors

- Reputation Research the company’s reputation and read client testimonials to understand their reliability and service quality. - Experience with Similar Equipment Ensure the movers have experience with the specific types of machinery you need to relocate. - Insurance and Licensing Check that the company is fully insured and licensed for moving heavy equipment to protect your assets.

- Comprehensive Services Look for companies that offer a full range of services, including dismantling, packing, transportation, installation, and post-move support.

Conclusion

In conclusion, professional machine shop equipment movers play a vital role in the manufacturing industry. Their expertise, equipment, and safety protocols are essential for efficient and safe relocations of heavy machinery. By investing in professional moving services, businesses can minimize downtime, reduce risks, and ensure that their equipment is set up correctly in its new location, ultimately contributing to enhanced productivity and operational success. As manufacturers continue to navigate the complexities of growth and technological advancements, the importance of reliable moving partners cannot be overstated.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025