machine skates and rollers

An Overview of Machine Skates and Rollers Essential Tools for Heavy Lifting

In the world of industrial lifting and transportation, machine skates and rollers play a crucial role. These devices are engineered to facilitate the movement of heavy machinery, equipment, and other substantial loads with relative ease. From construction sites to warehouses, machine skates and rollers are indispensable tools that enhance efficiency, safety, and productivity. This article explores the types, applications, benefits, and best practices associated with machine skates and rollers.

Understanding Machine Skates

Machine skates are robust platforms equipped with wheels or rollers, designed to transport heavy machinery across flat surfaces. Typically made from high-quality steel and featuring a low-profile design, skates can support significant weights while maintaining stability. They come in various sizes and configurations, making them suitable for different types of machinery, including generators, transformers, and large industrial equipment.

One of the primary advantages of using machine skates is their ability to maneuver in tight spaces, which is often a requirement in industrial settings. They can be used to move equipment into position for maintenance, installation, or relocation without the need for cranes or other heavy lifting equipment. This versatility saves time and labor costs while minimizing the risk of damage to the machinery.

The Role of Rollers

Rollers, on the other hand, are often simple cylindrical devices that ease the movement of heavy loads. They can be used in conjunction with machine skates or independently. Rollers are typically placed underneath the load, allowing it to be rolled along a surface with minimal effort.

There are many types of rollers, including plain rollers, swivel rollers, and heavy-duty rollers. Each type has specific applications based on the weight and the type of surface over which the load will be moved. For instance, heavy-duty rollers are designed for extremely heavy items, while swivel rollers can provide more maneuverability, allowing for 360-degree movement.

Applications of Machine Skates and Rollers

Machine skates and rollers find use in various industries, including manufacturing, construction, oil and gas, and warehousing. Their applications range from moving large machinery during installation to relocating heavy equipment for servicing.

In manufacturing plants, machine skates can be used to transport assembled units to different assembly lines or to load and unload equipment from trucks. In construction, they facilitate the maneuverability of heavy site equipment, ensuring that operations can continue smoothly.

machine skates and rollers

Moreover, in warehouses, machine skates and rollers can simplify the logistics of moving inventory or equipment

. By reducing the need for extensive manual labor, they enhance safety and efficiency, enabling workers to focus on other critical tasks.Benefits of Using Machine Skates and Rollers

The key benefits of employing machine skates and rollers are numerous. First and foremost, they significantly improve safety by enabling smoother, more controlled movements of heavy loads, reducing the risk of injury and accidents. By minimizing the need for manual lifting, they also help prevent strain injuries among workers.

Additionally, the use of machine skates and rollers can lead to cost savings. By streamlining the moving process, businesses can reduce labor hours and increase productivity. This efficiency is especially beneficial in tight schedules or during critical operations where time is of the essence.

Furthermore, machine skates and rollers are versatile and reusable tools. They can be utilized in different environments and scenarios, providing businesses with a flexible solution for various lifting and transportation needs.

Best Practices for Using Machine Skates and Rollers

To ensure the safe and effective use of machine skates and rollers, it is essential to adhere to certain best practices. First, always assess the load's weight and dimensions to select the appropriate skates or rollers capable of handling the specific requirements. Overloading these tools can lead to accidents and equipment failure.

It is also crucial to maintain clear communication among team members when moving heavy loads. Designating a person to direct the operation can enhance safety and ensure everyone is aware of the movements taking place.

Moreover, operators should regularly inspect machine skates and rollers for signs of wear or damage. Keeping these tools in optimal condition is vital for safe and efficient operation.

Conclusion

Machine skates and rollers are essential tools in the landscape of heavy lifting and industrial transportation. Their capacity to facilitate the movement of heavy loads safely and efficiently makes them invaluable in various industries. By understanding their functions, applications, and best practices, businesses can enhance their operational efficiency while ensuring the safety of their workforce. Through the smart utilization of these tools, the challenge of moving heavy machinery becomes not a daunting task but a manageable one, ultimately contributing to the success of any industrial operation.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

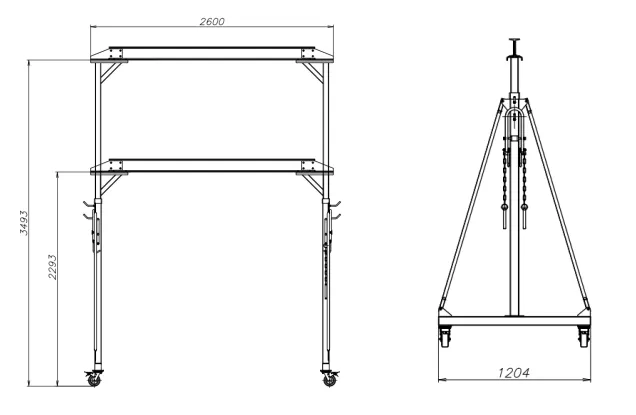

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025