machine to move pallets

The Evolution of Machines to Move Pallets A Transformative Shift in Warehouse Operations

In today's fast-paced industrial landscape, the efficiency of supply chain operations plays a crucial role in determining a company's success. As businesses strive for greater productivity and effectiveness, the need for robust solutions to streamline processes becomes paramount. Among these solutions, machines designed to move pallets have emerged as essential tools in modern warehousing and logistics. This article delves into the evolution of these machines, exploring their significance, various types, and the benefits they offer.

Pallets have long been the backbone of material handling, serving as the primary means for transporting goods within warehouses, distribution centers, and manufacturing facilities. Traditionally, manual labor was the norm for moving pallets, which proved to be inefficient and often hazardous. Workers required complex physical strength and coordination, which could lead to fatigue, injuries, and increased operational costs. The advent of machines to move pallets has transformed this aspect of material handling, paving the way for improved safety, efficiency, and productivity.

The Evolution of Machines to Move Pallets A Transformative Shift in Warehouse Operations

Enter the electric pallet jack—a powered version of its manual counterpart. With an electric motor to assist in lifting and moving pallets, these machines have revolutionized the pallet moving process. Electric pallet jacks can handle heavier loads with greater speed, making them particularly advantageous in larger warehouses where quick turnaround times are essential. Their ease of use and efficiency not only improves productivity but also enhances the overall work environment by reducing operator fatigue.

machine to move pallets

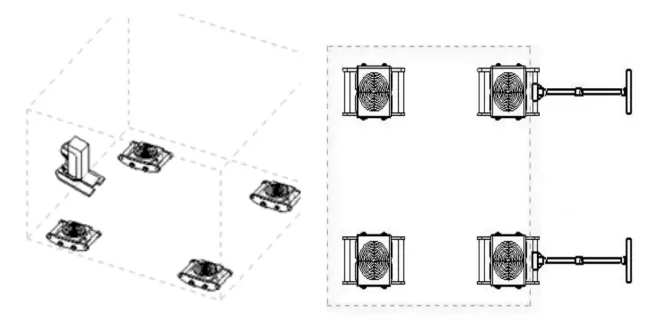

As technology continues to advance, so too does the complexity of machines designed for moving pallets. Automated guided vehicles (AGVs) and autonomous mobile robots (AMRs) represent the next frontier in pallet movement. These cutting-edge machines can navigate warehouse environments autonomously, transporting pallets from one location to another without human intervention. They use sensors and sophisticated navigation systems to avoid obstacles, follow designated paths, and optimize routes for maximum efficiency. The integration of AGVs and AMRs into supply chain operations has the potential to significantly reduce labor costs and enhance operational agility.

The benefits of using machines to move pallets extend beyond just efficiency and safety. By implementing such technology, companies can improve their inventory management, reduce the likelihood of product damage during transportation, and ultimately enhance customer satisfaction. An effective material handling system that incorporates these machines allows businesses to respond more quickly to market demands, thus maintaining competitiveness in an ever-evolving marketplace.

Furthermore, the adoption of machines for pallet movement aligns with broader trends towards automation and Industry 4.0. As more warehouses embrace digital transformation, the integration of Internet of Things (IoT) technology allows for real-time tracking and monitoring of pallets and inventory levels. This data-driven approach not only helps streamline operations but also informs strategic decision-making.

In conclusion, machines designed to move pallets play a pivotal role in modern warehousing and distribution. From the humble pallet jack to sophisticated automated vehicles, these machines have significantly improved efficiency, safety, and productivity in material handling operations. As technology continues to evolve, so too will the capabilities of these machines, paving the way for even greater innovations in the realm of logistics and supply chain management. The future undoubtedly holds exciting prospects for businesses willing to embrace these advancements, ultimately reinforcing the critical importance of efficient pallet movement in a competitive landscape.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025