machine to move pallets

The Rise of Machines in Pallet Movement A Game Changer for Logistics

In today's fast-paced world, the logistics and supply chain industries are experiencing a seismic shift, driven by the increasing demand for efficiency and speed. At the forefront of this transformation is the use of machines to move pallets, a crucial component in the handling of goods and materials across warehouses and production floors. This technological advancement is not merely a trend; it represents a fundamental rethinking of how goods are stored, managed, and transported, ultimately revolutionizing operations for businesses worldwide.

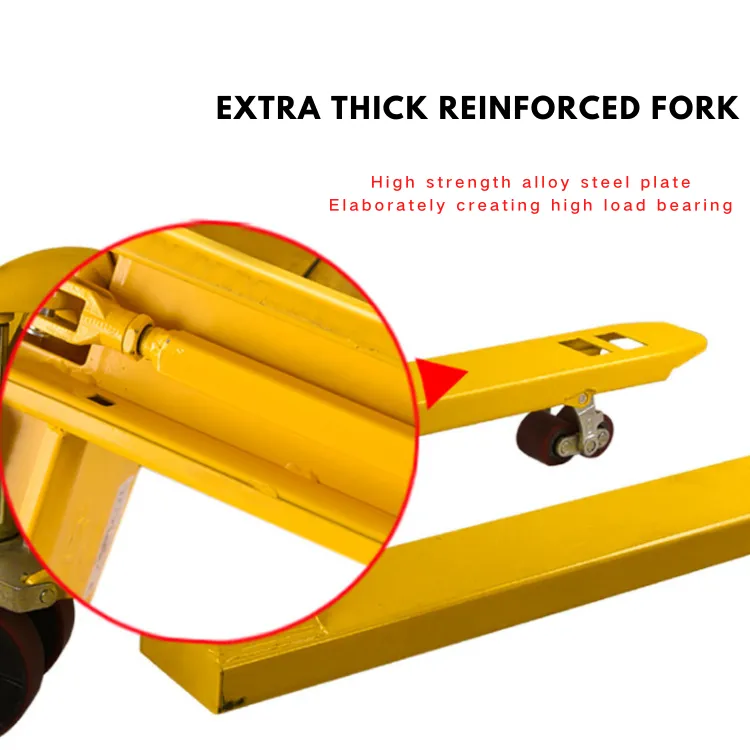

Pallets are ubiquitous in warehousing and transportation. They serve as the base for stacking products, making it easier to move large quantities with forklifts, pallet jacks, and other handling equipment. However, manual handling of pallets has its challenges. Workers can quickly become fatigued, leading to decreased productivity and, more critically, an increased risk of accidents and injuries. This is where machines come into play, offering a safer, more efficient alternative.

The Rise of Machines in Pallet Movement A Game Changer for Logistics

One significant advantage of using machines for pallet movement is the increase in operational efficiency. Automated systems can work continuously without the need for breaks, which dramatically increases the throughput of goods. For example, in a bustling warehouse, a fleet of autonomous forklifts can operate simultaneously, reducing the time taken to move pallets from one location to another. According to industry estimates, organizations implementing automated pallet movement systems have reported productivity improvements of over 30%. This increase not only helps to meet growing customer demands but also allows companies to reduce operational costs.

machine to move pallets

Moreover, the safety aspect cannot be overlooked. Machinery minimizes the physical strain on workers and significantly reduces the risk of injuries associated with manual lifting and moving. Automated systems are equipped with safety features that prevent collisions and ensure that pallets are handled without risk to human operators. In an industry where workplace safety is paramount, the shift toward machine-operated pallet movement offers a promising solution.

Furthermore, the integration of these machines into existing logistics systems enhances data collection and analysis. Many modern pallet-moving machines come equipped with IoT (Internet of Things) technology, allowing them to communicate with warehouse management systems. This connectivity provides real-time data on inventory levels, location of goods, and the overall efficiency of operations. Businesses can leverage this data to make informed decisions, improve forecasting, and streamline their supply chain processes.

However, the transition to automated pallet movement systems is not without its challenges. The initial investment costs can be significant, and companies must carefully evaluate the cost-benefit ratio. Additionally, there may be resistance from workers who fear job losses due to automation. It is essential for organizations to manage this transition thoughtfully, ensuring that employees are upskilled and integrated into new workflows that complement automated systems rather than replace them.

In conclusion, the movement of pallets using machines represents a pivotal development in the logistics industry. As technology continues to evolve, the benefits of automation will likely become even more pronounced. Companies embracing these innovations stand to gain a competitive edge in an increasingly crowded marketplace, underscoring the importance of adaptability and forward-thinking in modern business operations. By recognizing the value of automated pallet movement, organizations can not only enhance their operational efficiency but also pave the way for a safer and more resilient workforce.

-

Unlock Seamless Relocation with Our Heavy Equipment Moving ExpertiseNewsJun.06,2025

-

Unleash Unrivaled Flexibility with Our Adjustable Gantry CraneNewsJun.06,2025

-

Unleash Heavy-Duty Efficiency with Our Industrial Gantry Crane SolutionsNewsJun.06,2025

-

Revolutionize Steel Handling with Our Magnetic Lifter RangeNewsJun.06,2025

-

Master Equipment Mobility with Premium Machinery Mover SolutionsNewsJun.06,2025

-

Elevate Your Material Handling with Magnetic Lifter TechnologyNewsJun.06,2025

-

YS Permanent Lifting Magnets: The Smarter Way to Handle SteelNewsMay.22,2025